As we venture into 2025, the landscape of automation machinery manufacturing is poised for significant transformation. The integration of advanced technologies, coupled with the ever-growing demand for efficiency and precision in production processes, is reshaping the way manufacturers operate. In this dynamic environment, staying abreast of the top trends in automation is not just beneficial but essential for businesses aiming to maintain a competitive edge in the industry.

In the coming years, automation machinery manufacturing will increasingly leverage innovations such as artificial intelligence, machine learning, and robotics to optimize operations. These advancements promise to enhance productivity, reduce human error, and streamline workflows, allowing manufacturers to meet the evolving needs of the marketplace. Additionally, sustainability and smart manufacturing practices will play a crucial role as companies strive to balance efficiency with environmental responsibility, making the adoption of these trends more critical than ever.

This exploration of the 2025 top trends in automation machinery manufacturing highlights the pivotal changes that industry players must acknowledge and embrace. By understanding and implementing these trends, manufacturers can position themselves for success amid the complexities of a rapidly evolving industrial landscape.

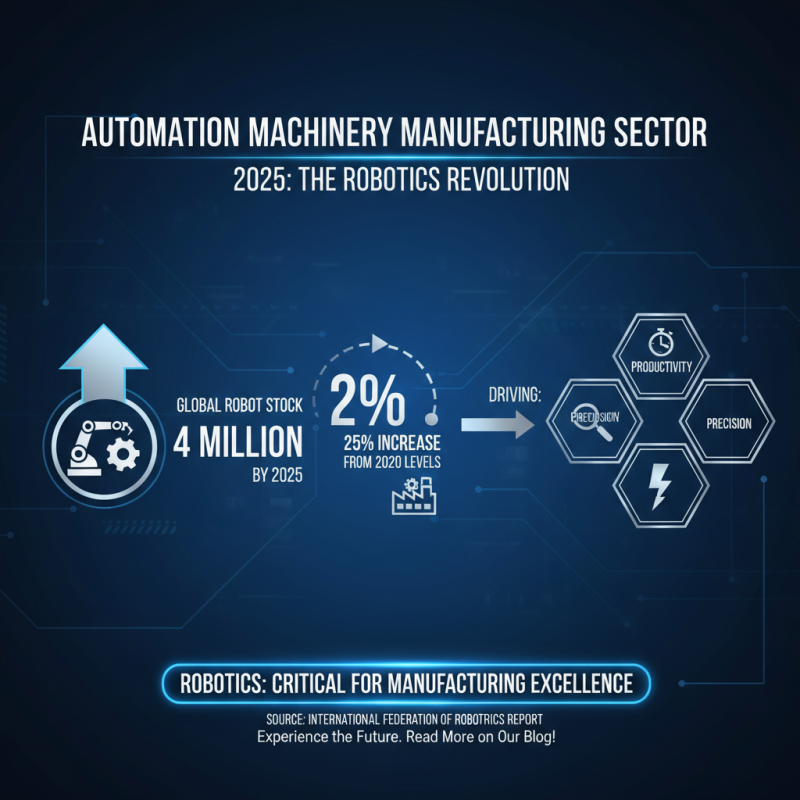

In 2025, the automation machinery manufacturing sector is poised to experience a significant shift driven by the rising integration of robotics. According to a report by the International Federation of Robotics, the global stock of operational industrial robots is expected to reach 4 million units by 2025, marking a 25% increase from 2020 levels. This surge reflects the growing recognition of robotics as a critical component in enhancing productivity, precision, and efficiency within manufacturing processes.

The adoption of robotics not only streamlines production but also addresses the ongoing labor shortages faced by many industries. A study conducted by McKinsey estimates that automation could augment the productivity of manufacturing sectors by as much as 30% by 2030. This trend is particularly evident in sectors such as automotive and electronics, where robotics is employed for repetitive tasks, allowing human workers to focus on more complex and creative responsibilities. As companies invest in advanced robotics solutions, the synergy between human skills and robotic efficiency will redefine operational strategies within automation machinery manufacturing.

The integration of AI technologies in manufacturing processes has emerged as a pivotal trend in the automation machinery industry. As manufacturers strive for greater efficiency and precision, AI-driven solutions are being deployed to analyze vast datasets, enabling real-time decision-making and predictive maintenance. By harnessing machine learning algorithms, companies can optimize production schedules, reduce downtime, and enhance product quality. The result is a more agile manufacturing environment that can quickly adapt to changing market demands.

Moreover, the integration of AI enhances collaboration between machines and human operators. Intelligent systems can provide valuable insights and recommendations that empower workers to make informed decisions on the shop floor. For instance, AI algorithms can analyze operator performance and suggest training programs tailored to improve skills where needed. This symbiotic relationship not only boosts productivity but also fosters a culture of continuous improvement within manufacturing teams.

As we move towards 2025, the integration of AI technologies is set to redefine standard practices in automation, empowering manufacturers to achieve unprecedented levels of operational excellence.

The automation machinery manufacturing industry is increasingly embracing sustainability as a core principle, driven by both regulatory mandates and market demands. According to a report from the International Society of Automation, around 70% of manufacturers are implementing sustainable practices to reduce their environmental footprint. This trend encompasses significant investments in energy-efficient technologies and environmentally friendly materials. For instance, using biodegradable lubricants and advanced automation systems can lead to a 30% reduction in resource consumption during the manufacturing process.

Furthermore, the integration of circular economy principles within automation machinery production is gaining traction. A recent study by the World Economic Forum estimates that transitioning to circular practices could generate $4.5 trillion in economic benefits globally by 2030. This involves redesigning machines for easier disassembly and recycling, minimizing waste, and maximizing the lifecycle of materials. As companies prioritize sustainability, they are also finding that eco-friendly operations can lead to cost savings, enhanced brand reputation, and compliance with increasingly stringent regulations aimed at reducing carbon emissions. Thus, sustainability is not just a trend; it is becoming an essential aspect of competitive manufacturing strategies in the automation machinery sector.

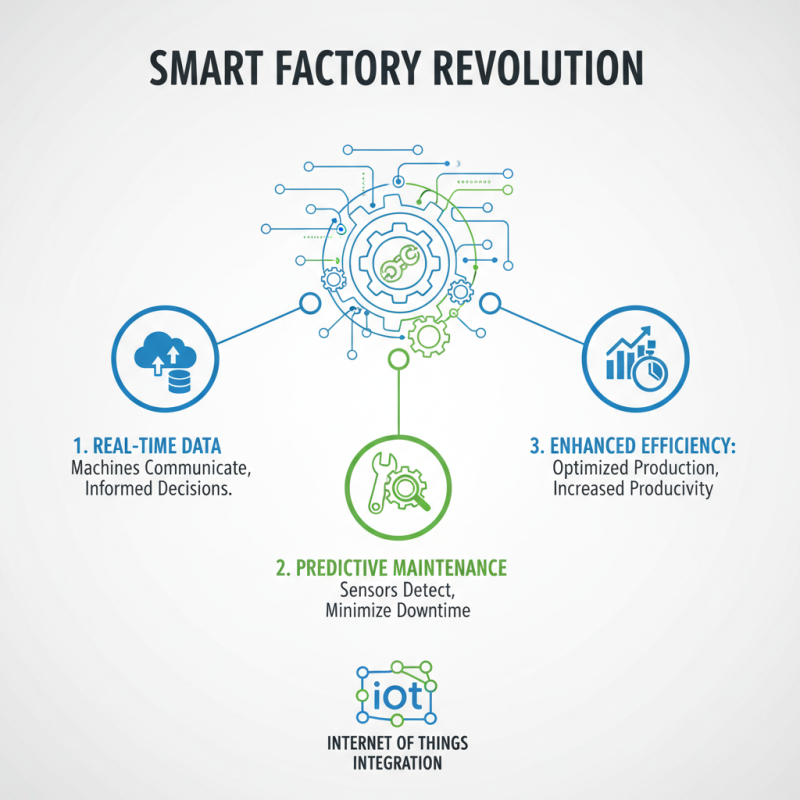

The integration of the Internet of Things (IoT) into automation machinery manufacturing is revolutionizing the way smart factories operate. By enabling machines to communicate with each other and their operators, IoT technology fosters a more interconnected and efficient production environment. This allows for real-time data collection and analysis, leading to informed decision-making that can significantly reduce downtime and enhance productivity. For instance, predictive maintenance powered by IoT sensors can identify potential equipment failures before they occur, thereby minimizing disruption and extending the lifespan of machinery.

Furthermore, the advancements in IoT are driving the evolution of smart factory solutions, making them more adaptable and responsive to changing market demands. With the ability to collect vast amounts of operational data, manufacturers can optimize workflows and improve resource allocation. IoT-enabled analytics allow for greater visibility into the manufacturing process, enabling more precise adjustments and enhancing overall operational efficiency. As manufacturing becomes more data-driven, leveraging IoT in automation not only streamlines processes but also empowers companies to innovate and stay competitive in an increasingly automated industry.

As industrial automation systems become increasingly sophisticated, the importance of cybersecurity cannot be overstated. In 2025, the integration of advanced technologies—such as IoT, AI, and machine learning—will significantly enhance manufacturing efficiency. However, this complexity also creates new vulnerabilities, making it essential for manufacturers to prioritize cybersecurity measures. Implementing strong security protocols not only protects sensitive data but also ensures the continuity of operations in case of cyber threats.

Tips: Regularly update your software and firmware to mitigate potential security gaps. Conduct vulnerability assessments to identify weaknesses in your automation systems. Employee training on cybersecurity awareness is also crucial, as human error often poses the greatest risk.

Moreover, the adoption of automated systems means that manufacturers must cultivate a culture of cybersecurity within their organizations. Establishing clear policies and procedures around data protection can significantly reduce risks. Collaborating with cybersecurity experts can further enhance a company's resistance to cyber attacks and ensure compliance with industry standards. As automation continues to evolve, proactively strengthening your cybersecurity framework will be vital to safeguarding your manufacturing operations.

| Trend | Description | Impact on Manufacturing | Cybersecurity Consideration |

|---|---|---|---|

| AI Integration | Utilizing artificial intelligence to enhance operational efficiency. | Improved productivity and predictive maintenance. | AI systems can be vulnerable to data breaches. |

| IoT Connectivity | Increased use of Internet of Things devices for real-time monitoring. | Enhanced visibility of processes and resource management. | Must ensure devices are safeguarded against unauthorized access. |

| Robotic Automation | The use of robotics for tasks traditionally performed by human workers. | Improves precision and reduces labor costs. | Robots can be targeted by cyberattacks if not properly secured. |

| Data Analytics | Leveraging data analytics for better decision-making. | Facilitates informed strategic planning and action. | Sensitive data must be protected from breaches. |

| Cybersecurity Measures | Implementing advanced cybersecurity protocols in automation systems. | Reduces risk of cyber incidents affecting operations. | Critical for maintaining the integrity of automation systems. |

We’re here to help and answer your questions.