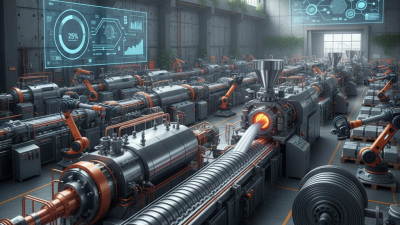

The aluminium extrusion industry in the UK has witnessed remarkable growth over recent years, driven by innovation and an increasing demand for lightweight yet durable materials in various applications. According to a recent report published by the Aluminium Federation, the UK's aluminium extrusion market is projected to grow by 4% annually, reflecting a rising interest in sustainable and efficient manufacturing processes. Industry expert Dr. Helen Smith, a leading figure in the aluminium extrusion UK sector, emphasizes the importance of this growth: "Aluminium extrusion not only strengthens our manufacturing capabilities but also supports our commitment to sustainability."

As industries across the UK embrace the benefits of aluminium extrusion, they are discovering its versatility in applications ranging from construction to automotive. The lightweight nature of aluminium, combined with its excellent corrosion resistance and recyclability, positions it as a key material in the quest for sustainable development. Understanding the top benefits of aluminium extrusion can help businesses capitalize on its potential, leading to improved efficiency and performance. This article delves into the top 10 advantages of aluminium extrusion, empowering UK manufacturers to harness the full spectrum of opportunities presented by this remarkable process.

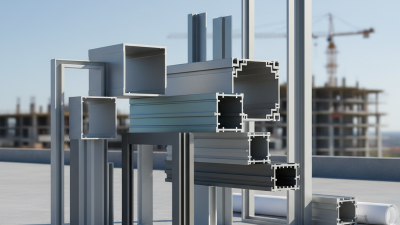

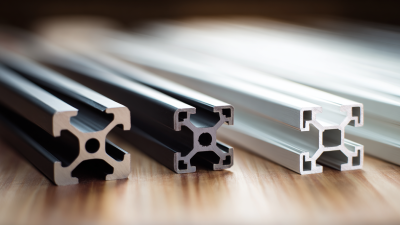

Aluminium extrusion is a manufacturing process that involves the shaping of aluminium alloy into specific cross-sectional profiles by forcing it through a die. This technique is particularly significant in the UK, where its versatility and sustainability align with growing industrial demands. The extrusion process allows for intricate designs and lightweight structures, making it an ideal choice for various applications, including construction, transportation, and consumer goods. By extruding aluminium, manufacturers can create components that are both strong and malleable, catering to the exact needs of different projects.

One of the key advantages of aluminium extrusion lies in its environmental benefits. Aluminium is infinitely recyclable, which minimizes the ecological footprint associated with production. In the UK, where there’s a strong push towards sustainability and reducing carbon emissions, aluminium extrusion fits perfectly within the framework of eco-friendly manufacturing. Moreover, the ability to produce complex shapes without excessive waste further enhances its relevance in reducing material costs and environmental impact. As industries in the UK continue to innovate, the adoption of aluminium extrusion is expected to grow, driven by its efficiency and adaptability to contemporary engineering challenges.

| Benefit | Description | Application Examples |

|---|---|---|

| Lightweight | Aluminium is significantly lighter than other metals, making it easier to handle and transport. | Construction, automotive components |

| Corrosion Resistance | The natural oxide layer protects aluminium from corrosion, extending its lifespan. | Outdoor structures, marine applications |

| Recyclability | Aluminium can be recycled multiple times without losing quality, reducing environmental impact. | Beverage cans, window frames |

| Versatile Design | Aluminium extrusion allows for custom shapes and profiles, enhancing design flexibility. | Architectural features, industrial parts |

| Thermal Conductivity | Aluminium is an excellent conductor of heat, making it ideal for heat sinks and radiators. | Electronics, HVAC systems |

| Electrical Conductivity | Aluminium is a good conductor of electricity, suitable for wiring without the weight of copper. | Power lines, electrical connectors |

| Low Maintenance | Aluminium requires minimal maintenance compared to other materials, saving time and costs. | Exterior building facades, signage |

| Strength | Despite its lightweight, aluminium provides high strength-to-weight ratios for structural applications. | Bridges, aircraft components |

| Cost-Effectiveness | Aluminium extrusion can be a more economical solution than other manufacturing processes. | Mass-produced parts, consumer goods |

Aluminium has become a preferred material in various industries, especially within the UK, thanks to its unique characteristics that make it ideal for extrusion processes. One of the most significant attributes of aluminium is its excellent weight-to-strength ratio. This means that despite being lightweight, extruded aluminium profiles exhibit remarkable strength, making them suitable for applications ranging from construction to automotive components. The ability to easily manipulate aluminium into complex shapes further enhances its versatility, allowing manufacturers to produce tailored solutions that meet specific design requirements.

Another key characteristic is aluminium's resistance to corrosion. This property is particularly important in the UK, where variable weather conditions can pose challenges for materials used in outdoor applications. The natural oxide layer that forms on the surface of aluminium serves as a protective barrier, allowing extruded products to maintain their appearance and functionality over time. Moreover, aluminium's recyclability adds to its appeal, aligning with growing sustainability efforts in the manufacturing industry. By utilizing aluminium extrusion, companies can benefit from a material that not only meets performance demands but also supports eco-friendly practices.

This chart illustrates the top 10 benefits of aluminium extrusion in the UK, highlighting the key characteristics that make aluminium an ideal material for extrusion.

Aluminium extrusion offers numerous benefits across various industries in the UK, making it a popular choice for manufacturers and designers alike. One of the key advantages is its lightweight nature, which enhances efficiency in transportation and handling. This property is particularly valuable in the automotive and aerospace sectors, where reducing weight can lead to better fuel economy and overall performance. Additionally, the strength-to-weight ratio of aluminium allows for the creation of durable components without adding unnecessary bulk.

Another significant benefit of aluminium extrusion is its versatility in design. The extrusion process enables the production of complex shapes and profiles that are tailored to specific applications. This customization is especially advantageous in sectors such as construction and electronics, where unique specifications are often required. Furthermore, aluminium's excellent corrosion resistance ensures longevity and minimizes maintenance costs, making it an ideal choice for outdoor applications and environments that are subject to harsh conditions. With these properties, aluminium extrusion continues to play a critical role in driving innovation and efficiency in various industries throughout the UK.

Aluminium extrusion offers significant environmental benefits that make it a compelling choice for manufacturers and consumers alike. One of the primary advantages is its recyclability. Aluminium can be recycled indefinitely without losing its properties, which drastically reduces the demand for virgin material extraction. The recycling process consumes only a fraction of the energy needed to produce new aluminium from ores, leading to lower CO2 emissions and a smaller carbon footprint. This sustainable approach not only conserves natural resources but also aligns with global efforts to reduce waste and promote circular economies.

Moreover, aluminium extrusion processes enable lightweight structures that enhance energy efficiency in various applications, from transportation to construction. Lighter materials used in vehicles, for example, contribute to better fuel economy and reduced greenhouse gas emissions. Additionally, aluminium’s durability and resistance to corrosion ensure a longer lifespan for products, further minimizing the environmental impact associated with manufacturing, maintenance, and disposal. By choosing aluminium extrusion solutions, industries can play a vital role in fostering sustainability and innovation while meeting the growing environmental demands of consumers.

Aluminium extrusion has gained significant traction in the UK manufacturing sector due to its cost-effectiveness and versatility. According to a report by the Aluminium Federation, using aluminium extrusions can reduce production costs by up to 30% compared to traditional manufacturing methods. This is largely due to aluminium's lightweight nature, which leads to lower shipping costs and easier handling during the production process.

Furthermore, the ability to create complex shapes with precision means that less material waste occurs, translating into further savings for manufacturers.

Tips: To maximize the cost-effectiveness of aluminium extrusion, companies should consider investing in high-quality dies upfront. Although initial costs may seem higher, improved die durability can lead to lower long-term costs by minimizing the frequency of replacements. Additionally, thorough planning of extrusion processes and optimal design can significantly contribute to efficiency, allowing manufacturers to leverage the full benefits of aluminium.

Moreover, the recyclability of aluminium adds to its cost-effectiveness. Industry analyses indicate that recycled aluminium requires only 5% of the energy needed to produce new aluminium, resulting in substantial energy savings and reduced material costs. By implementing recycling processes, manufacturers can lower their overall production expenses while supporting sustainable practices, making aluminium extrusion not just a financially savvy choice but also an environmentally responsible one.

We’re here to help and answer your questions.