In the world of manufacturing and construction, the demand for custom solutions has never been greater. One standout option gaining traction is bespoke aluminium extrusion, a highly versatile process that allows for the creation of tailor-made aluminium profiles designed to meet specific project requirements. Unlike standard extrusions, bespoke aluminium extrusion provides the flexibility to design shapes and sizes that perfectly fit the unique needs of a project, thereby enhancing overall functionality and aesthetic appeal.

The benefits of bespoke aluminium extrusion are both extensive and compelling. For instance, it enables architects and engineers to push the boundaries of design without compromising on material performance. This method not only facilitates a high level of customization but also ensures that the end product is lightweight, durable, and eco-friendly. Additionally, bespoke aluminium extrusion can result in cost savings over time as it reduces the need for additional components or modifications, streamlining the construction process and minimizing waste. Embracing bespoke aluminium extrusion can elevate the quality and efficiency of your projects, making it an attractive option in today's competitive market.

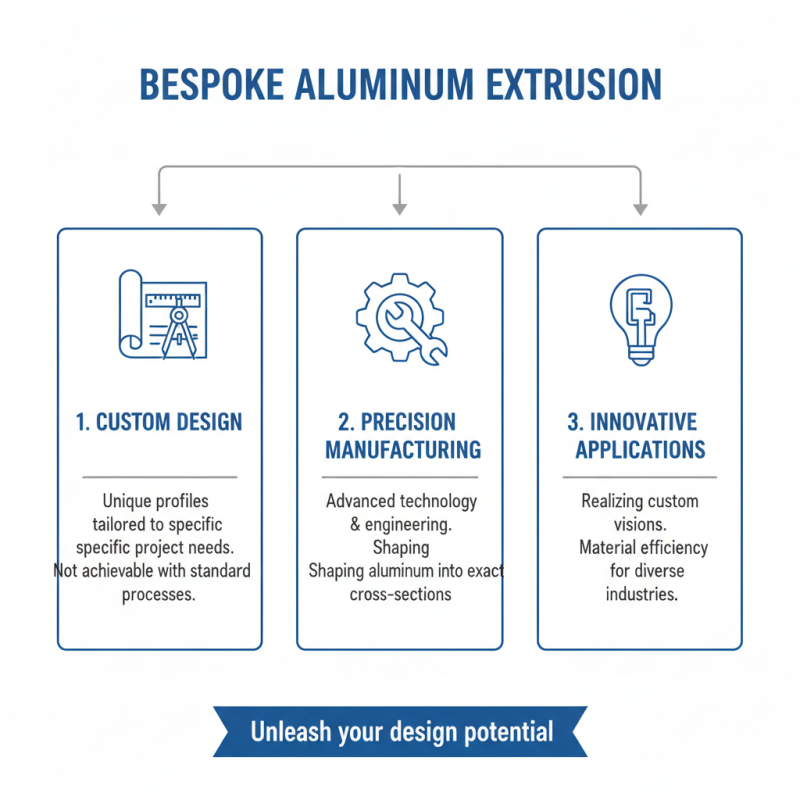

Bespoke aluminium extrusion refers to the custom manufacturing process of shaping aluminium into specific profiles to meet unique project requirements. This highly versatile method allows for the creation of a wide variety of cross-sectional shapes tailored to specific applications, which cannot be achieved through standard extrusion processes. By leveraging advanced technology and precise engineering, bespoke aluminium extrusion enables designers and engineers to realize their innovative visions while maintaining material efficiency.

The benefits of bespoke aluminium extrusion extend beyond mere aesthetics and design freedom. One of the primary advantages is the ability to achieve specific performance characteristics, such as strength, weight reduction, and corrosion resistance, making it an ideal choice for industries ranging from automotive to construction. Additionally, customized profiles allow for seamless integration into existing systems, enhancing functionality and often reducing assembly time. This flexibility in design, combined with the lightweight nature of aluminium, provides significant advantages for projects where efficiency and performance are critical.

Aluminium extrusion is a highly versatile manufacturing process that involves shaping aluminium alloy by forcing it through a specially designed die. This method allows for the creation of complex cross-sectional shapes, making it an ideal choice for various applications. The extrusion process begins with heating the aluminium alloy to a malleable state, which is then pushed through the die using a hydraulic press. The result is a continuous length of aluminium that can be cut to the required size.

One of the primary benefits of bespoke aluminium extrusion is its adaptability. Designers can create components that meet specific geometric, mechanical, and aesthetic requirements without the need for extensive tooling modifications. Additionally, the process produces minimal waste, making it an economical option for custom projects.

**Tips:** Consider integrating additional design elements into your extrusion, such as channels for wiring or grooves for easy assembly. This can significantly improve functionality while saving time during installation. Furthermore, always collaborate closely with your extrusion provider to refine designs and ensure that your specifications align with the capabilities of the extrusion process.

| Dimension | Description | Benefits |

|---|---|---|

| Material | Aluminium alloys | Lightweight yet strong |

| Customization | Tailor-made shapes and sizes | Specific to project requirements |

| Process | Aluminium is heated and forced through a die | Efficient and versatile production |

| Finishing Options | Anodizing, painting, and more | Enhanced aesthetics and durability |

| Applications | Construction, automotive, and furniture | Wide range of industrial uses |

Bespoke aluminium extrusion is a manufacturing process that tailors aluminium profiles to meet specific design requirements, offering distinct advantages for various projects. One of the primary benefits is the remarkable versatility and customization it provides. According to industry reports, custom extruded aluminium accounts for approximately 50% of the global aluminium extrusion market, indicating a significant shift towards tailored solutions. This flexibility allows architects and designers to create unique shapes that can enhance the aesthetic appeal and functionality of structures, from residential buildings to commercial installations.

Another key advantage of bespoke aluminium extrusion is its cost-effectiveness over time. While the initial investment may be higher than standard profiles, custom extrusions can lead to substantial savings in material waste and labor costs. The precise fit reduces the need for additional machining or adjustments during installation, streamlining the construction process. Additionally, aluminium's inherent properties, such as lightweight yet robust nature, contribute to lower shipping costs and easier handling on-site. Reports suggest that projects utilizing bespoke profiles may see up to a 30% reduction in overall production time when tailored solutions are implemented, emphasizing the efficiency and practicality of bespoke aluminium extrusion in contemporary projects.

Bespoke aluminium extrusion is increasingly becoming a go-to solution across various industries, primarily due to its versatility and customizable nature. According to a report by Smithers Pira, the global aluminium extrusion market is expected to reach $150 billion by 2025, largely driven by sectors such as construction, automotive, and aerospace. In construction, bespoke extrusions allow architects and engineers to create unique designs, enhancing both aesthetic appeal and structural integrity. These tailored solutions can meet specific load requirements and environmental conditions, making them ideal for modern building projects.

In the automotive industry, bespoke aluminium extrusions are utilized for lightweight components that improve fuel efficiency and reduce emissions. The International Aluminium Institute reports that lightweighting vehicles can enhance fuel efficiency by approximately 6-8% for every 10% reduction in vehicle weight. This not only meets regulatory standards but also addresses consumer demand for greener technologies. Similarly, in the aerospace sector, custom extrusions contribute to the development of innovative aircraft designs, where minimizing weight while maximizing strength is crucial. With advancements in extrusion technology, tailoring these components has become more accessible, leading to greater adoption across various applications.

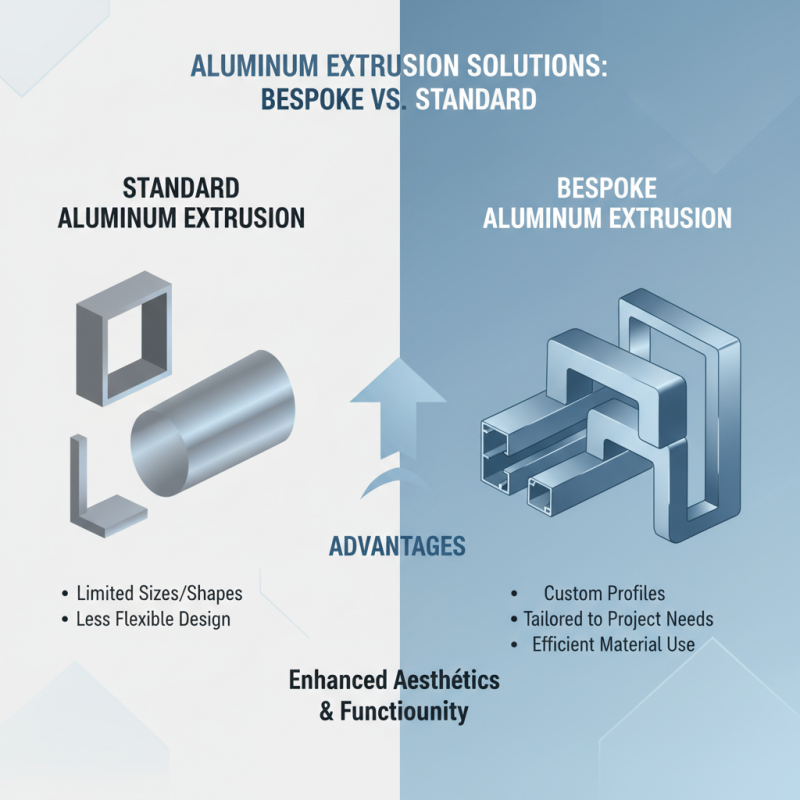

When it comes to aluminium solutions for projects, bespoke aluminium extrusion offers a distinct advantage over standard options. Bespoke extrusion allows for the design and production of customised profiles that meet specific project requirements, whereas standard solutions are often limited in terms of sizes and shapes. This flexibility means that architects and engineers can create uniquely tailored components that enhance the aesthetic appeal and functionality of their designs. Furthermore, bespoke solutions can contribute to a more efficient use of materials, reducing waste during the manufacturing process.

Tips: When considering bespoke aluminium extrusion for your project, it’s essential to collaborate closely with your manufacturer early in the design phase. This ensures that your requirements can be accurately captured and translated into an effective design.

Moreover, the ability to modify dimensions and integrate additional features, such as holes or channels, makes bespoke extrusion a versatile option for complex constructions. Standard aluminium solutions may fall short in accommodating these added functionalities, which can limit the overall effectiveness of a project. By choosing bespoke options, you not only gain design freedom but also the potential for improved performance tailored specifically to your needs.

Tips: Always request samples of bespoke profiles before final production to evaluate whether the design meets your expectations and functional needs. This proactive approach can save both time and costs later in the project lifecycle.

We’re here to help and answer your questions.