In the ever-evolving landscape of manufacturing, the selection of the right extrusion profiles plays a critical role in the success of various projects. As industry expert Dr. Emily Thompson states, “Choosing the right extrusion profiles not only enhances the structural integrity of your product but also significantly impacts its performance and cost-efficiency.” With a myriad of options available, it can often be overwhelming for engineers and designers to navigate through the intricate details of extrusion profiles to find the best fit for their unique applications.

Understanding the specific requirements of your project is essential in making an informed decision. Factors such as material properties, desired thermal and mechanical characteristics, and aesthetic considerations all influence the choice of extrusion profiles. Moreover, the effectiveness of an extrusion profile can determine the feasibility and longevity of the final product, making it a pivotal element in project planning and execution.

As projects become more specialized and complex, a strategic approach to selecting extrusion profiles is crucial. This article aims to provide insights and practical guidance on how to choose the right extrusion profiles for your projects, ensuring that they meet both functional requirements and design aspirations while maintaining cost-effectiveness.

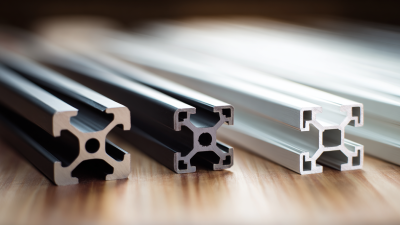

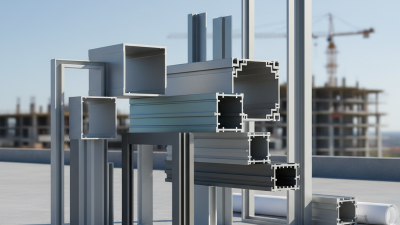

Extrusion profiles play a crucial role in various projects across multiple industries, making it essential to understand the different types available. Commonly used materials include aluminum, PVC, and steel, each with distinct properties that cater to specific applications. According to the "2023 Global Extrusion Industry Report", the demand for aluminum profiles is projected to grow by 4.7% annually due to their lightweight nature and corrosion resistance, making them ideal for construction and automotive sectors.

When selecting the appropriate extrusion profile, it’s vital to consider the intended use, load-bearing capacity, and environmental factors. For example, structural profiles must meet rigorous strength standards, while decorative profiles may prioritize aesthetics without compromising functionality. Engaging with industry resources like the "Aluminum Extrusion Technology Handbook" can provide insights into the latest innovations and best practices in profile selection.

Tip: Always assess the thermal and mechanical properties of the material when choosing an extrusion profile, as these factors influence the profile's longevity and performance under stress. Additionally, consulting with experts or engaging in community forums can offer valuable tips and real-world experiences that guide your decision-making process.

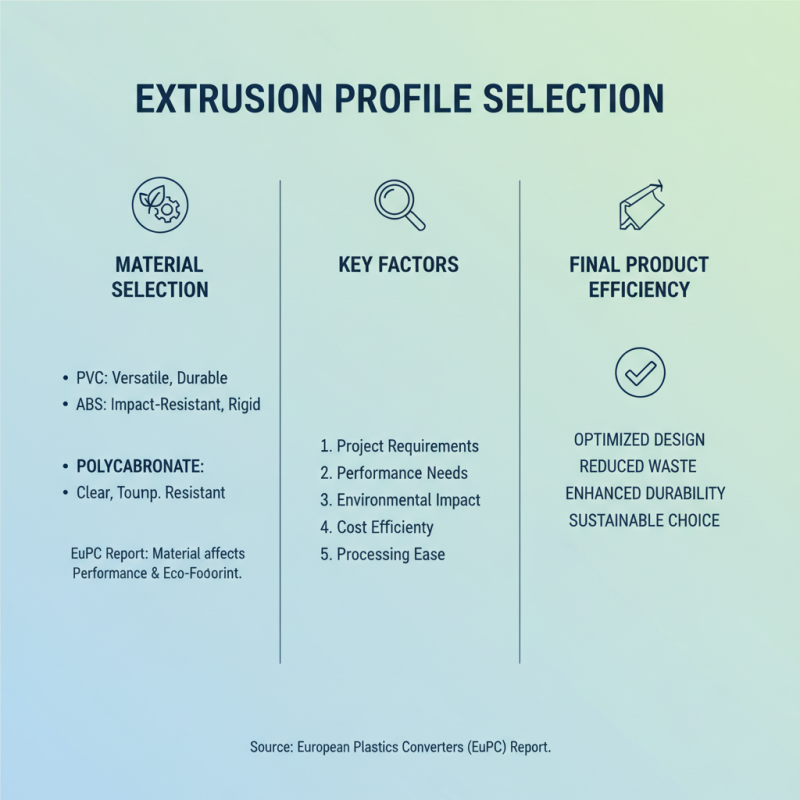

When selecting extrusion profiles for your projects, it's essential to consider several key factors that can influence the efficiency and effectiveness of the final product. One of the most important aspects is the material selection. According to a report by the European Plastics Converters (EuPC), the choice of material can impact not only the performance but also the environmental footprint of the extrusion process. Commonly used materials like PVC, ABS, and polycarbonate have distinct properties suited for different applications, so understanding the specific requirements of your project is crucial.

Another vital factor is the design of the profile itself. The complexity of the extrusion shape can significantly affect production costs and lead times. As highlighted in data from the American Institute for Packaging and the Environment, intricate designs may result in higher tooling and processing costs. It's advisable to work closely with design engineers to ensure that the profile meets both functional needs and cost constraints.

**Tips:** Always prototype your extrusion profiles to test functionality before full-scale production. This step can mitigate risks and reveal necessary adjustments early in the process. Additionally, think about the end-use of the profiles—consider how they will be processed, painted, or finished, as these factors can also dictate the type of material you select. A thorough understanding of these parameters will help streamline your selection, leading to more successful project outcomes.

When selecting extrusion profiles for your projects, understanding the material properties is paramount in ensuring optimal profile performance. Different materials exhibit unique characteristics, such as strength, flexibility, and resistance to environmental factors. For instance, a high-strength alloy may be preferable for structural applications, while a more flexible polymer might be ideal for parts requiring bending or molding.

Tips: When evaluating materials, consider the application's end-use environment. Will the profile be exposed to extreme temperatures or corrosive elements? Doing thorough research on the material's resistance to these conditions can save time and money on replacements and repairs.

Additionally, the production process itself can impact the performance of the extrusion profiles. The choice of extrusion technique, such as direct or indirect extrusion, should align with the material's properties to achieve desired results. For example, materials that are difficult to extrude may require specialized processes to ensure they maintain structural integrity and performance standards.

Tips: Always consult with material specialists and test prototypes under real-world conditions to verify their performance. This proactive approach can help troubleshoot potential issues before full-scale production begins.

Evaluating Material Properties: How They Affect Extrusion Profile Performance

When selecting extrusion profiles for projects, a critical factor to consider is the balance between quality and budget. A recent industry report predicts that the global market for extrusion profiles will reach approximately $95 billion by 2025, emphasizing the growing demand for these components across various sectors, including automotive, construction, and consumer goods. To maximize project efficiency, stakeholders must perform a cost-benefit analysis that weighs the durability and performance of materials against their initial and long-term costs.

A thorough analysis should include the total lifecycle costs of extrusion profiles, which encompass not only initial purchase prices but also maintenance, energy efficiency, and replacement costs. According to research by the Plastic Industry Association, high-quality profiles, although potentially more expensive upfront, often provide significant savings over time due to their extended usable life and reduced need for maintenance and replacements. This approach supports the idea that investing in quality can lead to more sustainable project outcomes, offering both economic benefits and enhanced performance in the long run. Thus, understanding the nuances of material selection and their corresponding costs is essential in making informed decisions for future projects.

| Profile Type | Material | Cost per Meter (USD) | Weight (kg/m) | Strength (MPa) | Applications |

|---|---|---|---|---|---|

| Rectangular | Aluminum | 4.50 | 1.2 | 230 | Frames, Supports |

| T-Slot | Aluminum | 5.00 | 1.5 | 220 | Modular Structures |

| Circular | Steel | 6.50 | 0.8 | 250 | Pipes, Handrails |

| L-Shape | Aluminum | 4.75 | 1.0 | 210 | Brackets, Corners |

| U-Shape | PVC | 3.00 | 0.6 | 150 | Casing, Trim |

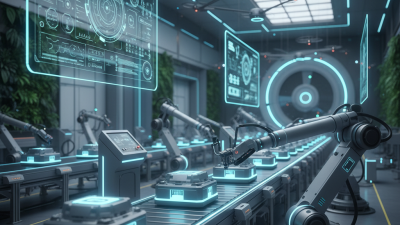

In 2025, the selection of extrusion profiles will be heavily influenced by emerging industry trends and innovations aimed at improving performance and sustainability. As companies seek more efficient solutions, advancements in materials technology will play a crucial role. Lightweight composites and enhanced thermoplastics are gaining traction, offering superior strength-to-weight ratios while minimizing environmental impact. These materials not only improve energy efficiency in manufacturing but also contribute to the lifecycle sustainability of products, making them an increasingly popular choice for various applications.

Furthermore, the integration of smart manufacturing and automation technologies is revolutionizing the extrusion process. Industry players are increasingly adopting digital fabrication techniques and real-time monitoring systems, which enable precise control over the extrusion parameters. This not only enhances the quality of the profiles produced but also allows for customization tailored to specific project requirements. Additionally, automation in extrusion lines can streamline production, reduce waste, and lower operational costs, making it an appealing option for businesses looking to remain competitive in a rapidly evolving market. As innovation continues to shape the extrusion industry, staying ahead of these trends will be crucial for selecting the appropriate profiles that meet both project demands and future sustainability goals.

We’re here to help and answer your questions.