In the competitive landscape of manufacturing, selecting the right aluminium extrusion machine is crucial for the success of any business focusing on aluminium products. As industry expert Dr. Emily Carter, a renowned authority in aluminium processing technology, aptly states, “Investing in the right aluminium extrusion machine can dramatically enhance productivity and reduce operational costs.” This insight underscores the significance of careful consideration when choosing machinery for aluminium extrusion.

Aluminium extrusion is a vital process that allows manufacturers to create complex shapes with precision and efficiency. With advancements in technology, businesses are presented with a myriad of options that can cater to different operational needs. It is imperative for entrepreneurs to assess their specific requirements, including production volume, desired product specifications, and budget constraints, in order to make an informed decision.

Choosing the best aluminium extrusion machine not only influences the quality of the end product but also impacts the overall operational workflow. As the market continues to evolve, staying updated on the latest innovations and trends in aluminium extrusion technology is essential for businesses aiming to maintain a competitive edge. Understanding the intricacies of these machines and how they align with organizational goals will pave the way for sustainable growth and success in the aluminium industry.

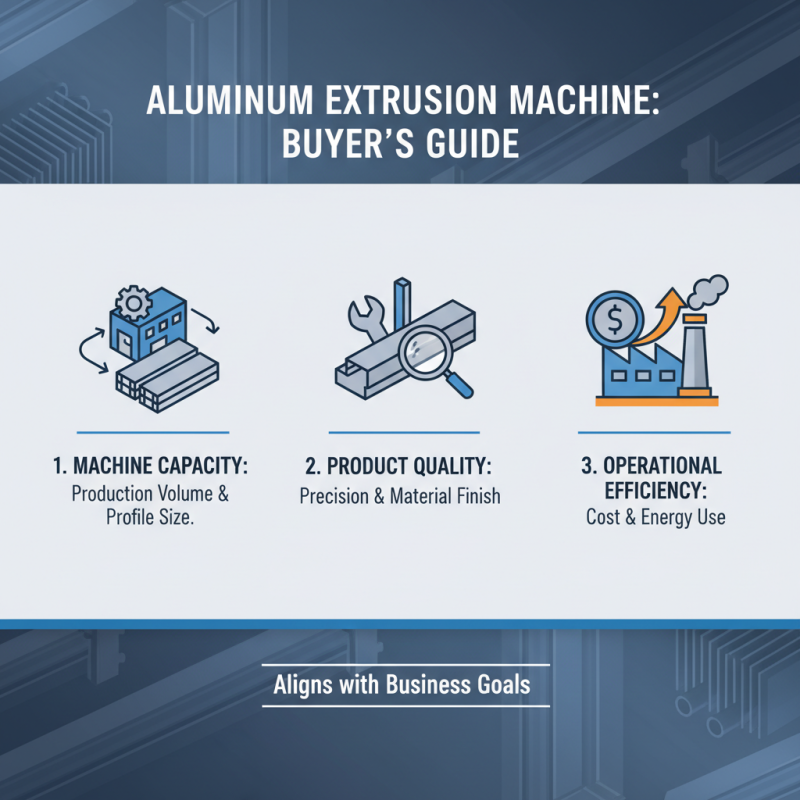

When selecting the best aluminium extrusion machine for your business, several factors come into play that can significantly influence your operational efficiency and product quality. First and foremost, the capacity of the machine is crucial. Consider the volume of production required and the specific dimensions of the extrusions you plan to manufacture. Machines vary widely in terms of their output capacity and the types of profiles they can produce, so aligning your choice with your production goals is key.

Another important aspect to factor in is the machine's technological features. Look for advancements that enhance productivity, such as automation capabilities, control systems, and energy efficiency. A machine equipped with modern technology can reduce labor costs and minimize waste, ultimately leading to a better return on investment. Additionally, consider the support and maintenance services offered by the manufacturer. Opting for a machine with readily available parts and technical support can help mitigate downtime and ensure smooth operation, which is essential for maintaining a competitive edge in the market.

When selecting the right aluminium extrusion machine for your business, understanding the types of machines available and their specific applications is crucial. The primary types of aluminium extrusion machines include direct extrusion presses and indirect extrusion presses. Direct extrusion involves pushing the aluminium billet through the die using a ram, suitable for producing profiles with complex shapes. Indirect extrusion, on the other hand, allows for cleaner outputs and is ideal for certain high-strength materials, with the die being outside the extrusion chamber. According to a recent market report, the global aluminium extrusion machinery market is projected to grow at a CAGR of 4.3% from 2021 to 2028, highlighting the increasing adoption of these technologies.

In addition to the basic types, the choice of machine can also depend on the specific needs of your business. For example, if you are focusing on mass production and uniformity, a large direct extrusion press may be ideal. Conversely, for small batches with varied dimensions, a smaller setup might be more efficient. Always consider the maximum extrusion force, the heating method, and the die design, as these factors directly affect production quality and efficiency.

**Tips:** Before purchasing, evaluate your production volume and expected growth. Make sure to consult with industry experts and consider visiting operational facilities to get insights into different machine performances. Additionally, investing in a machine with features that allow for future upgrades can be beneficial as technology evolves, facilitating long-term productivity and cost-effectiveness.

| Machine Type | Features | Applications | Capacity (kg/h) | Price Range (USD) |

|---|---|---|---|---|

| Direct Extrusion Machine | Simple design, high production efficiency | Standard profiles, construction, automotive parts | 100-300 | $50,000 - $150,000 |

| Indirect Extrusion Machine | Less die wear, better surface finish | Complex profiles, aerospace components | 80-250 | $70,000 - $200,000 |

| Hydraulic Extrusion Machine | High control precision, adaptable for different profiles | Custom profiles, electronics housings | 150-400 | $60,000 - $180,000 |

| Screw Extrusion Machine | Versatile material handling, continuous production | Aluminium composites, industrial applications | 200-500 | $80,000 - $250,000 |

| Vertical Extrusion Machine | Space-saving design, suitable for smaller factories | Smaller profiles, decorative elements | 50-150 | $40,000 - $120,000 |

When selecting the best aluminium extrusion machine for your business, evaluating key specifications is crucial for optimal performance. One of the primary factors to consider is the machine's capacity, which refers to the maximum weight and size of the materials it can handle. A higher capacity machine will allow for larger extrusions, improving efficiency and reducing production time. Additionally, look for machines equipped with advanced temperature control systems, as maintaining consistent heat levels during the extrusion process is vital for ensuring high-quality output.

Another important specification to examine is the extrusion speed. Machines that offer adjustable speed settings can provide greater flexibility to meet varying production requirements. This feature is particularly advantageous when dealing with different product lines or transitioning between various shapes. Moreover, the machine's ability to produce intricate designs should not be overlooked. Investing in technology that supports complex tooling will enable your business to cater to a wider range of customer needs, ultimately enhancing competitiveness in the market.

When considering the purchase of an aluminium extrusion machine, budgeting plays a crucial role in ensuring that your business can maintain operational efficiency without straining finances. The initial cost of the machine is just one aspect; businesses must also factor in additional expenses such as installation, training, and necessary accessories. It is essential to conduct thorough market research to identify a range of options and choose a machine that offers the best balance between performance and price.

Maintenance costs are another significant consideration. Regular maintenance is critical to prevent costly downtime and repairs. Businesses should anticipate expenses related to routine checks, replacement parts, and potential upgrades to keep the machinery operational and efficient. Establishing a maintenance schedule and budgeting for these ongoing costs will help avoid unexpected financial burdens in the future. Additionally, considering warranties and service agreements can further safeguard against unforeseen expenses, making it essential to review these options carefully during the purchasing process.

When selecting the best aluminium extrusion machine for your business, partnering with reputable manufacturers and suppliers is crucial. A trustworthy manufacturer not only ensures the quality and durability of their equipment but also offers robust customer support and service. It's important to research suppliers that have a proven track record in the industry, as they are likely to provide machines that meet international standards and utilize the latest technology. Look for companies that have built strong reputations through years of experience and customer satisfaction.

Additionally, consider the range of offerings from these manufacturers. A reliable supplier should provide not only the extrusion machines themselves but also a complete suite of services, including installation, maintenance, and training for your staff. This comprehensive approach can help you avoid common pitfalls and downtime associated with poor setup or inadequate understanding of the machinery. By choosing manufacturers who prioritize quality and customer service, you can ensure that your investment in aluminium extrusion equipment will support the growth and efficiency of your business for years to come.

We’re here to help and answer your questions.