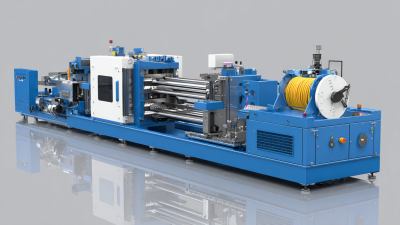

In the evolving landscape of manufacturing, selecting the right aluminium cutting machine has become paramount for workshops aiming to enhance efficiency and precision. According to a recent report by Smith & Associates, the global demand for aluminium cutting machines is projected to grow by 6.5% annually, driven by increasing applications in automotive, aerospace, and construction industries. This surge underscores the critical need for manufacturers to invest in high-quality machinery that meets their specific operational requirements.

Industry expert Dr. Emily Liu, a renowned figure in manufacturing technology, emphasizes the importance of making informed decisions when choosing cutting equipment. She states, "The right aluminium cutting machine not only improves production capabilities but also significantly reduces waste and operational costs." With advancements in technology, modern machines now offer features such as automated cutting systems and integrated software solutions, allowing for enhanced precision and productivity. As workshops assess their options in 2025, understanding the nuances of different models and their respective features will be essential in making the best choice for their operational needs.

When selecting the best aluminium cutting machine for your workshop in 2025, it is crucial to consider several key factors that influence performance and efficiency. The global CNC metal cutting machine tools market is projected to witness significant growth, expanding from $64.64 billion in 2025 to an estimated $82.78 billion by 2032, indicating a compound annual growth rate (CAGR) of 3.6%. This growth reflects the increasing demand for advanced metal fabrication technologies, emphasizing the need for precision and reliability in aluminium cutting machines.

One essential factor to consider is the type of cutting technology employed by the machine. Options such as laser cutting, waterjet cutting, and traditional saw cutting each offer distinct advantages depending on the specific applications in your workshop. Furthermore, the integration of automation features can enhance operational efficiency, allowing for faster production times and reduced labor costs. As the sheet metal fabrication services market is anticipated to grow from approximately $18.50 billion in 2025, investing in the right aluminium cutting machine not only improves productivity but also positions your workshop competitively in a rapidly evolving industry.

This chart compares the performance metrics of three different aluminium cutting machines in 2025 based on speed, precision, power consumption, weight, and price. It helps potential buyers make informed decisions when selecting the best machine for their workshop needs.

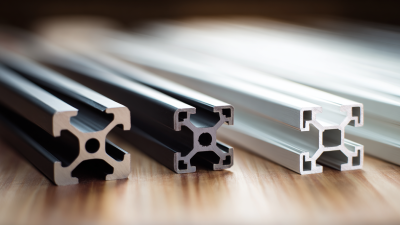

When selecting an aluminium cutting machine for your workshop, it's crucial to evaluate the different types of machines available. Bandsaws are a popular choice due to their versatility and ability to cut complex shapes. They utilize a continuous loop blade that can handle both straight cuts and curves, making them suitable for a variety of projects. However, bandsaws may require more setup time and regular blade maintenance to ensure optimal performance.

Circular saws, on the other hand, offer speed and efficiency for straight cuts. Their high-speed rotating blades can quickly slice through aluminium, making them ideal for large-scale operations or repeated cuts. While they excel in speed, users must be cautious about the quality of the cut and potential burrs, which can require additional finishing work.

Plasma cutters present another option, particularly for thicker aluminium sheets. They use a high-velocity jet of ionized gas to melt through the metal, resulting in clean, intricate cuts. Plasma cutters are especially valuable for fabrication shops where precision and detail are paramount. Choosing the best machine for your workshop ultimately depends on the specific needs of your projects, including the material thickness, cut complexity, and the required speed of operation.

| Cutting Machine Type | Advantages | Disadvantages | Ideal Usage | Cutting Thickness (mm) | Cost Range ($) |

|---|---|---|---|---|---|

| Bandsaw | Versatile, clean cuts, good for different shapes | Slower cutting speed, requires more space | Curved and intricate cuts | 0-50 | 500-3000 |

| Circular Saw | Fast cutting speed, ideal for straight cuts | Limited to straight cuts, may require finishing | Straight cuts and crosscuts | 0-100 | 200-1500 |

| Plasma Cutter | Fast and precise, capable of complex shapes | Requires ventilation, may be expensive | Thicker materials and intricate designs | 1-25 | 1000-5000 |

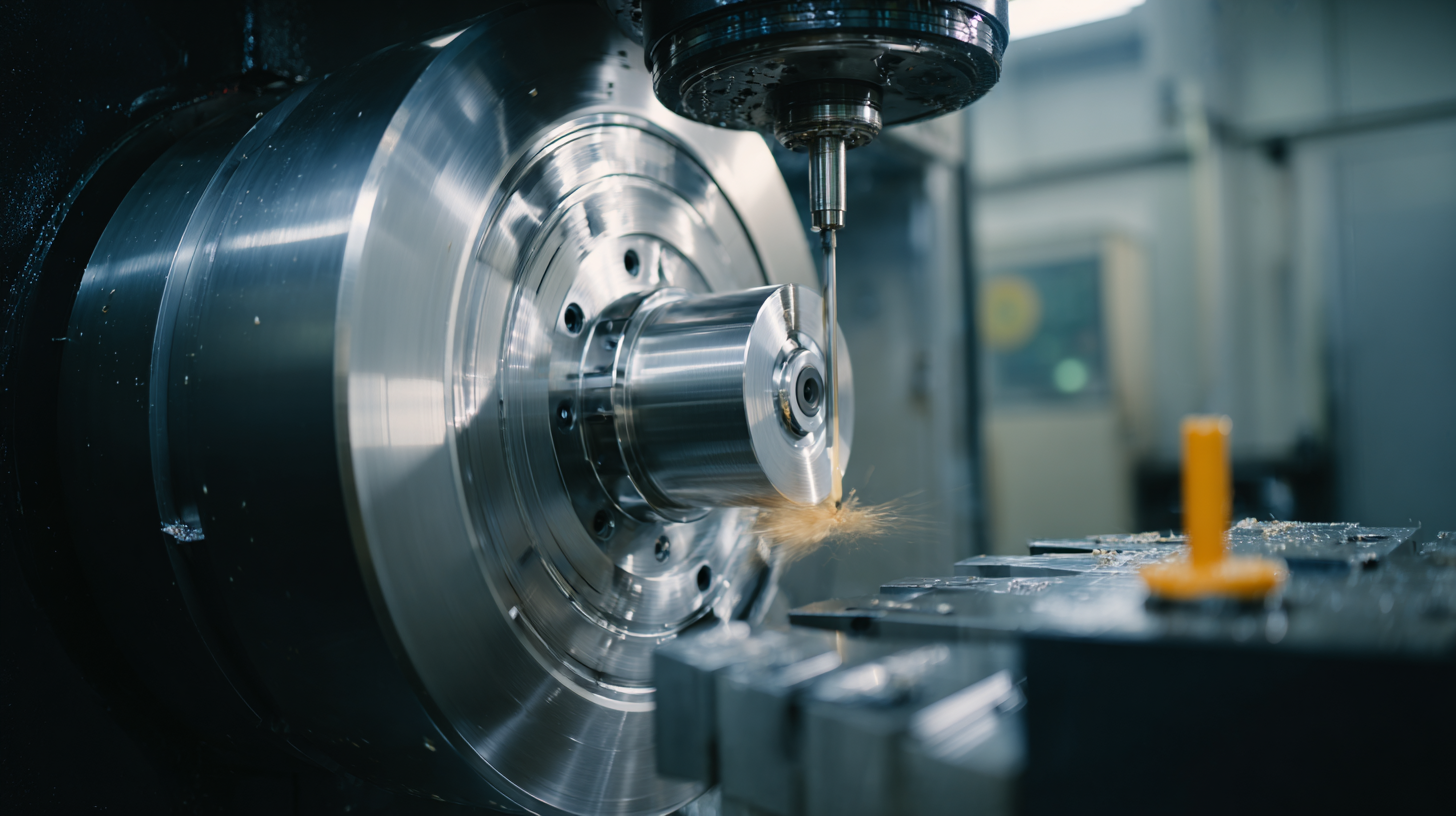

When selecting the best aluminum cutting machine for your workshop, understanding the dynamics of cutting speeds and feed rates is essential for maximizing efficiency and ensuring high-quality outcomes. Cutting speed refers to the rate at which the cutting tool engages the workpiece, while feed rate indicates how quickly the tool advances into the material. Both parameters significantly impact the surface quality and mechanical properties of the machined aluminum, making knowledge of these factors crucial for optimized operations.

When selecting the best aluminum cutting machine for your workshop, understanding the dynamics of cutting speeds and feed rates is essential for maximizing efficiency and ensuring high-quality outcomes. Cutting speed refers to the rate at which the cutting tool engages the workpiece, while feed rate indicates how quickly the tool advances into the material. Both parameters significantly impact the surface quality and mechanical properties of the machined aluminum, making knowledge of these factors crucial for optimized operations.

Recent advancements in machining technology have highlighted the importance of these parameters in achieving energy efficiency and improved cut quality. For instance, studies have shown that optimizing cutting speeds can enhance surface finish and reduce the kerf width during aluminum processing. Additionally, innovative tools designed for high-efficiency machining can further improve the balance between speed and feed rate, enabling manufacturers to meet the growing demand for lightweight, high-strength components across various industries, such as aerospace and automotive. By carefully selecting cutting machines that allow for precise control of these variables, workshops can achieve better performance and sustainability in their operations.

When choosing the best aluminium cutting machine for your workshop, there are several key features and technologies to consider. Modern machines are equipped with advanced cutting technologies such as CNC (Computer Numerical Control) systems which enhance precision and efficiency in cutting operations. These systems allow for intricate designs and improved repeatability, making them essential for professional workshops aiming for high-quality outputs.

Another important aspect to look for is the machine's ability to handle various thicknesses of aluminium. Many contemporary cutting machines come with adjustable settings that enable users to switch between different materials and thicknesses seamlessly. Additionally, look for machines that incorporate cooling systems to prevent overheating, which can lead to material warping or excessive tool wear.

Tips: Always assess the machine's build quality and durability; products made with robust materials tend to last longer and require less maintenance. Furthermore, consider the availability of customer support and spare parts, as this can significantly impact your shop's operational efficiency in the long run. Investing in a machine with an intuitive user interface can also streamline your workflow, ensuring that even less experienced operators can achieve great results with minimal training.

When selecting an aluminium cutting machine for your workshop in 2025, understanding the cost-effectiveness analysis is essential. The relationship between investment and performance will guide you toward making informed decisions that align with your operational needs. Machines that may appear more expensive upfront often offer superior technology, leading to increased efficiency and lower operational costs over time. These advanced models can provide more precise cuts, reduce material wastage, and minimize energy consumption, all of which can significantly enhance overall productivity.

Additionally, it is crucial to evaluate your workshop's specific requirements against the capabilities of various cutting machines. Consider factors such as the machine’s cutting speed, maintenance costs, and expected lifespan. A machine that excels in performance but has high maintenance demands may not offer the best long-term value, whereas a cost-efficient option could prove to be ineffective if it fails to meet your cutting needs. Therefore, a balance between initial investment, performance reliability, and operating costs will ensure that you choose the best aluminium cutting machine that not only fits your budget but also maximizes output and efficiency in your workshop environment.

We’re here to help and answer your questions.