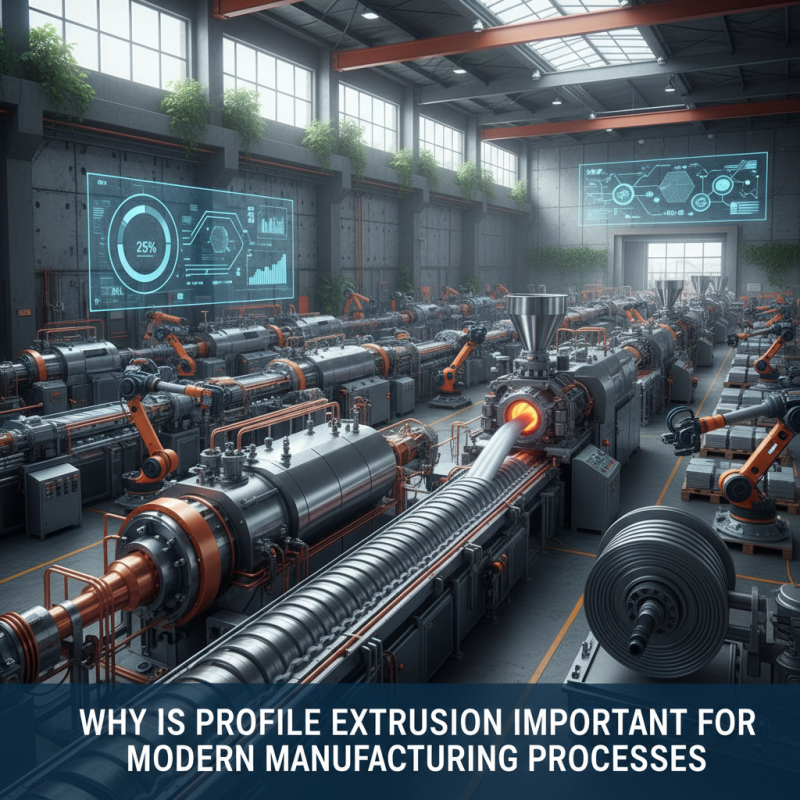

In the realm of modern manufacturing processes, profile extrusion has emerged as a critical technique that enhances production efficiency and material performance across various industries. According to a recent report by Smithers Pira, the global market for extrusion products is projected to reach $250 billion by 2025, demonstrating the growing reliance on this manufacturing method. Profile extrusion allows for the continuous shaping of materials into complex cross-sections, enabling manufacturers to create customized components tailored to specific applications with high precision and repeatability.

The importance of profile extrusion extends beyond mere production capabilities; it plays a pivotal role in reducing waste and energy consumption during the manufacturing process. A study by the Plastics Industry Association reveals that extrusion processes can lead to a 25% reduction in material waste compared to traditional manufacturing methods. This not only contributes to cost savings for manufacturers but also aligns with the global push for sustainable practices in manufacturing. As industries strive to meet both economic and environmental goals, the integration of profile extrusion is becoming an indispensable aspect of modern production strategies, highlighting its significance in fueling innovation and promoting efficiency.

Profile extrusion has emerged as a crucial process in modern manufacturing, primarily due to its ability to produce complex shapes and profiles efficiently. According to a report by the Freedonia Group, the U.S. market for plastic extrusion is expected to exceed $20 billion by 2025, underscoring the increasing reliance on this technique across various industries. This growth is predominantly driven by sectors such as construction, automotive, and consumer goods, where tailored profiles are essential for product functionality and aesthetics.

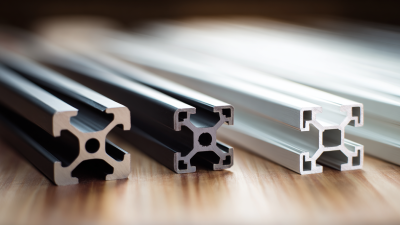

The importance of profile extrusion lies in its versatility and cost-effectiveness. This process allows manufacturers to create continuous lengths of profiles in a variety of materials, including thermoplastics and composites. The ability to produce specific cross-sectional shapes minimizes waste and optimizes material usage, contributing to sustainability goals—an aspect increasingly demanded by both consumers and regulatory bodies. Furthermore, advances in extrusion technology, including improved tooling and automation, have enhanced production speeds and consistency, leading to higher quality outputs. As reported by the Plastic Extruders Group, advancements in extrusion methods have increased production efficiency by up to 30%, emphasizing the role of profile extrusion in driving modern manufacturing practices.

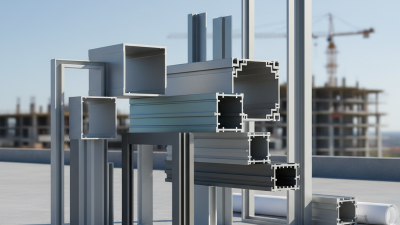

Profile extrusion is a vital manufacturing process utilized across various industries due to its ability to produce complex shapes with high precision and efficiency. According to the Freedonia Group, the U.S. market for plastic extrusion is projected to reach $36 billion by 2025, reflecting a significant demand driven largely by architectural and automotive sectors. Profile extrusion allows manufacturers to create specific profiles that are lightweight yet durable, catering to applications in construction, automotive, and consumer goods.

In the construction industry, profile extrusion plays a crucial role in producing window frames, doors, and tubing that contribute to energy efficiency and sustainability. The American Architectural Manufacturers Association reported that energy-efficient windows, often made through extrusion processes, could save homeowners up to $500 annually on energy costs.

Meanwhile, the automotive sector relies heavily on profile extrusion to manufacture lightweight and fuel-efficient components, significantly impacting overall vehicle performance. According to a recent report by MarketsandMarkets, the automotive plastics market is expected to reach $48.59 billion by 2026, indicating the growing importance of such materials in vehicle design.

Profile extrusion is a vital manufacturing process that offers numerous advantages over traditional techniques. One of the primary benefits is its efficiency in producing complex shapes with a consistent cross-section. According to the Society of Plastics Engineers, profile extrusion can achieve output rates of approximately 200 to 1,000 pounds per hour, making it significantly faster than methods like injection molding, which often have longer cycle times. This efficiency not only reduces production time but also lowers costs for manufacturers, facilitating higher profit margins and the ability to meet high-volume demands.

In addition to efficiency, profile extrusion allows for a greater flexibility in material selection. Various thermoplastics can be extruded, such as PVC, ABS, and polycarbonate, enabling manufacturers to tailor products to specific performance needs. A report by MarketsandMarkets indicates that the global plastic extrusion market is projected to reach USD 25.5 billion by 2025, underscoring the increasing reliance on this technique in various industries, including construction, automotive, and consumer goods. The ability to produce lightweight, durable, and customizable profiles makes profile extrusion an attractive option, enhancing its importance in modern manufacturing processes.

Profile extrusion plays a vital role in modern manufacturing processes, benefiting significantly from recent technological innovations. The introduction of advanced materials such as thermoplastics and bio-based resins has enabled manufacturers to push the limits of profile design and functionality. According to a report by the Freedonia Group, the demand for plastic extrusion is projected to reach $29 billion by 2025, underscoring the growing importance of techniques like profile extrusion which deliver enhanced customization and precision.

Furthermore, the integration of automation and Industry 4.0 principles into profile extrusion processes has optimized production efficiency and reduced waste. Companies are increasingly adopting real-time monitoring systems that utilize IoT technology for better quality control and predictive maintenance. A study by MarketsandMarkets predicts that automation in manufacturing will grow to a market size of $296.70 billion by 2026, highlighting how these technological advancements are shaping modern profile extrusion. The ability to quickly adapt to changing consumer demands and create complex profiles at scale is transforming industries, from construction to consumer goods.

Profile extrusion is a vital part of modern manufacturing, enabling the production of complex shapes and materials tailored to specific applications. However, the process faces several challenges that can hinder efficiency and quality. Common issues include material inconsistencies, blockages in the extruder, and difficulties in achieving precise dimensions. To address these challenges, manufacturers must implement stringent quality control measures and invest in advanced extrusion technologies.

Tips: Regular maintenance of extrusion equipment can prevent blockages and material degradation, ensuring smoother operation and higher-quality output. Additionally, conducting thorough material checks before extrusion can reduce the risks of inconsistencies in the final product.

Another significant challenge in profile extrusion is managing temperature fluctuations, which can lead to warping or degradation of the profiles being produced. Adopting temperature control systems can help maintain optimal conditions throughout the extrusion process. Furthermore, enhancing employee training on equipment usage and troubleshooting can significantly reduce downtime and improve overall production efficiency.

Tips: Establishing a routine training program for staff can empower them to handle equipment more effectively and quickly address common issues that may arise during the extrusion process.

We’re here to help and answer your questions.