In the rapidly evolving landscape of industrial equipment, innovations shape the future of efficiency. Experts are optimistic about advancements that drive productivity. John Smith, a leading figure in industrial engineering, once stated, "Innovation is the backbone of progress in industrial equipment." This sentiment resonates deeply as we approach 2026.

New technologies like automation and AI are revolutionizing operations. Machines become smarter and more capable, yet challenges remain. Not every innovation is a guaranteed success; some may fall short of expectations. For example, integrating AI involves a steep learning curve for many companies. The potential benefits are immense, but the path to implementation can be rocky.

The industrial equipment sector must embrace change while learning from setbacks. Understanding both the successes and failures is crucial. As we anticipate 2026, staying adaptable will determine how effectively innovations can enhance efficiency. Balancing optimism with realism drives true advancement in this essential industry.

The industrial sector is witnessing a wave of innovative technologies aimed at boosting efficiency. Automation tools, powered by artificial intelligence, are revolutionizing workflows. These solutions optimize processes and reduce manual labor, but they require careful implementation. Companies must train staff to work alongside these systems. This presents a challenge, as the learning curve may slow down initial productivity.

Another key innovation is the integration of IoT sensors in machinery. These devices collect real-time data, offering insights into performance and maintenance needs. While they enhance operational efficiency, reliance on technology can lead to vulnerabilities. Cybersecurity must be prioritized to protect sensitive information. Companies need to weigh the benefits against potential risks.

Sustainability is also becoming central to industrial equipment. Innovations focus on energy efficiency and waste reduction. However, pushing for greener solutions may strain budgets. There is a delicate balance between cost and environmental responsibility. Industries must reflect on their long-term goals to find sustainable paths forward. These emerging technologies pave the way for a more efficient future but require thoughtful implementation.

| Innovation Type | Description | Efficiency Benefits | Expected Impact Year |

|---|---|---|---|

| AI-Powered Predictive Maintenance | Utilizes AI to predict equipment failures before they occur. | Reduces downtime, increases productivity by up to 20%. | 2026 |

| IoT Integration | Connects equipment to the internet for real-time monitoring. | Enhances data collection and responsiveness to machine issues. | 2025 |

| Advanced Robotics | Utilizes collaborative robots for assembly and manufacturing tasks. | Improves production speed and flexibility in operations. | 2026 |

| Energy-Efficient Motors | New designs that reduce energy consumption in industrial processes. | Cuts energy costs by 15-30%, reducing carbon footprint. | 2025 |

| Blockchain for Supply Chain | Uses blockchain to improve transparency and traceability in supply chains. | Reduces fraud and errors, increases trust among partners. | 2026 |

In 2026, automation is reshaping the manufacturing landscape. AI and robotics take center stage, driving efficiency. Factories are leveraging machines for repetitive tasks, allowing human workers to focus on innovation. This shift not only speeds up production but also enhances precision. Many companies report higher productivity levels since implementing these advancements.

However, not everything is perfect. Some workers feel threatened by robots. Job displacement remains a concern for many in the industry. It’s crucial for businesses to address these fears openly. Training programs can help bridge the skills gap. Workers should embrace opportunities to learn alongside technology.

Tips: Foster a culture of collaboration between humans and machines. Encourage workers to adapt to new roles that machines create. Sharing success stories can motivate team members. Understanding the benefits of automation can ease resistance and lead to smoother transitions.

In 2026, eco-friendly equipment and materials are set to reshape the industrial landscape. A recent report indicates that companies prioritizing sustainable practices could reduce operational costs by 30%. This shift proves that going green isn't just a trend; it’s an economic necessity. Renewable materials, such as bio-based plastics and recycled metals, are becoming standards. These innovations help cut down waste and minimize carbon footprints.

Tip: Consider integrating alternative materials into your supply chain. This can enhance efficiency while benefiting the environment.

Some industries still hesitate to adopt these practices. Concerns about performance and initial costs linger. However, as research shows, the long-term savings often outweigh these doubts. For instance, using energy-efficient machinery can lead to a 25% decrease in energy consumption. Machines designed for sustainable production not only perform well but can also attract eco-conscious clients.

Tip: Train staff on sustainable practices. Knowledge boosts confidence in implementing green solutions effectively.

Embracing sustainability now can lead to a more resilient future, yet the journey is not without challenges. Reflecting on existing methods can reveal surprising inefficiencies. In the evolving industrial sector, those who adapt will thrive, while those who resist may find themselves left behind.

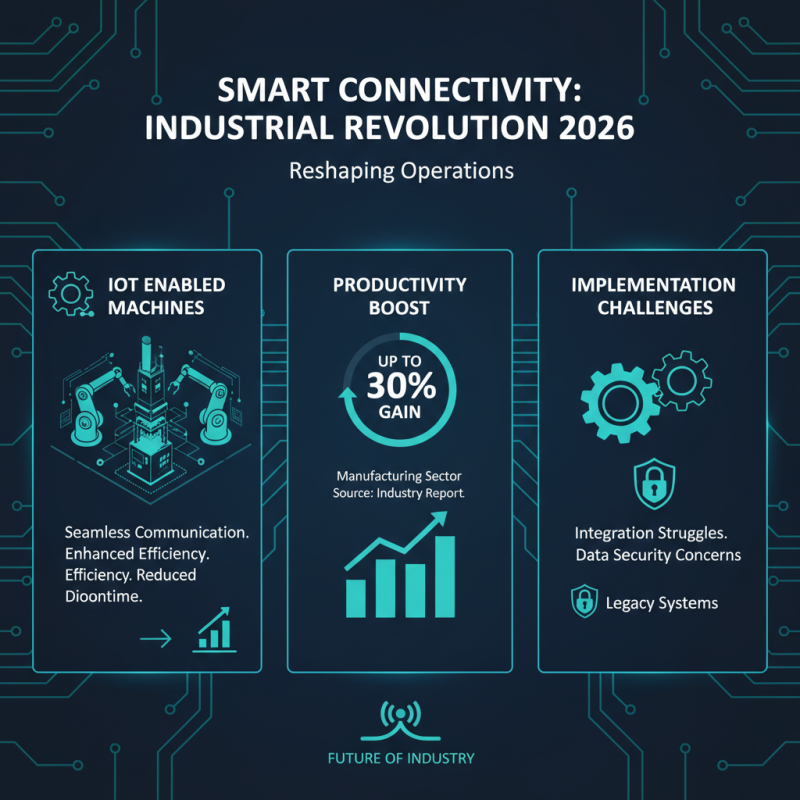

Smart connectivity is reshaping industrial operations dramatically in 2026. The Internet of Things (IoT) enables machines to communicate seamlessly. This connectivity enhances efficiency and reduces downtime. According to a recent industry report, IoT applications could boost productivity by up to 30% in manufacturing alone. However, challenges remain in implementation. Many companies struggle with integration.

Data analytics from IoT devices provide real-time insights. This allows for predictive maintenance, reducing equipment failures. The potential savings from reduced downtime can reach millions annually. Yet, not all firms capitalize on these innovations. A survey indicates that 40% of organizations lack the expertise to fully leverage IoT.

Security is another pressing issue. As more devices connect, the risk of cyber threats increases. Keeping data safe while maximizing utility is a delicate balance. Companies must invest in robust security solutions. The promise of smart connectivity is significant, but the path to success involves facing these complexities head-on.

Data analytics is transforming the industrial sector. In 2026, leveraging big data can enhance performance significantly. A recent report showed that companies using data analytics boost their operational efficiency by up to 25%. This is not just a trend; it’s a fundamental shift.

Industries now rely on real-time data to make informed decisions. Predictive analytics helps in anticipating equipment failures. This approach allows companies to minimize downtime and reduce costs. Finding the right data points is essential, but many companies struggle with overwhelming amounts of data. It’s crucial to have a strategy in place.

Tip: Focus on the most relevant data for your needs.

Data visualization tools can aid in understanding complex datasets. Yet, it's easy to misinterpret visuals, leading to poor decisions. Training employees on data literacy can help prevent this issue.

Tip: Regular training ensures that your team can effectively use data analytics.

The challenge is not just collecting data but using it meaningfully. Companies must continuously analyze and refine their approach. This iterative process is key to achieving optimal results in performance.

We’re here to help and answer your questions.