In today's rapidly evolving marketplace, industrial solutions hold significant value for business success. Companies face countless challenges. From rising operational costs to increasing competition, the stakes are high. To thrive, organizations must adapt and innovate. Industrial solutions provide a pathway to efficiency and growth. They streamline processes and enhance productivity. This approach often involves automation, advanced technologies, and data-driven insights.

Moreover, these solutions can lead to surprising results. For instance, a small change in workflow could save hours. Implementing smart management systems can allow a business to respond swiftly to market changes. However, many companies still hesitate. They may fear the costs or the complexity of integration. This reluctance can hinder progress. It's essential to reflect on these barriers and the potential they create. Embracing industrial solutions can unlock new opportunities. They are not just another expense; they can be a catalyst for transformation in modern business.

Industrial solutions refer to a range of specialized tools and methodologies that optimize operations in businesses today. These solutions can include automation, data analytics, and supply chain management systems. According to a recent report by McKinsey, companies that fully utilize industrial solutions can boost productivity by up to 20-30%. The shift towards smarter operations is not just a trend; it’s a necessity in a competitive landscape.

In practical terms, efficient industrial solutions streamline production processes, reduce waste, and enhance quality control. A study from Deloitte notes that 73% of manufacturers believe that adopting advanced technologies, like IoT, can yield significant cost savings. Yet, not all businesses find the transformation easy. Many struggle with integration challenges and workforce training. The hesitation to invest is often rooted in uncertainty about ROI.

Viewing industrial solutions as fundamental is vital. Without them, businesses risk inefficiency. Engaging with these advanced systems enables better decision-making and faster responses to changing market demands. However, implementation remains a hurdle for many. Companies must embrace continual learning to fully realize the potential of these industrial solutions.

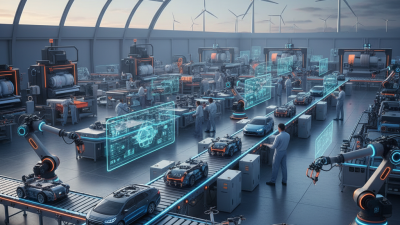

Industrial solutions provide vital advantages for contemporary businesses. Automating processes can lead to greater efficiency. For example, using robotics in manufacturing reduces human error. This enhances productivity and speeds up production times. Many companies have reported significant time savings.

Data analytics is another key benefit. By analyzing trends, businesses can make informed decisions. This helps in understanding customer preferences better. However, not all enterprises utilize this tool effectively. Some may overlook critical insights that improve operations. Adopting smart technologies can streamline logistics, leading to cost savings. Yet, the initial investment may seem daunting.

Collaboration tools enhance teamwork and communication. They allow teams to work seamlessly, regardless of location. However, some employees resist these changes. Training becomes essential to overcome this barrier. In the end, the implementation of industrial solutions can significantly impact success. Adapting to these tools is crucial for future growth.

In today’s fast-paced market, technology drives industrial solutions. According to a recent report, businesses adopting advanced technologies can see up to 30% gains in operational efficiency. Automation, IoT, and data analytics reshape how industries operate. Companies can monitor equipment in real-time, reducing downtime significantly. This adaptability is crucial, but not all businesses leverage these technologies effectively.

Yet, the integration of technology is not without challenges. A study highlighted that 60% of companies struggle with digital transformation. They face issues integrating new tools with existing systems. Training also poses a significant barrier, with employees often resistant to changes. As firms work to bridge these gaps, they risk falling behind competitors who have embraced innovation.

Interestingly, the impact of technology extends beyond mere efficiency. It fosters collaboration, enhances supply chain transparency, and improves customer satisfaction. Businesses that invest in these industrial solutions report higher profitability. However, the continuous evolution of technology demands ongoing investment and reflection on business strategies. Balancing costs with benefits remains a critical concern for many leaders.

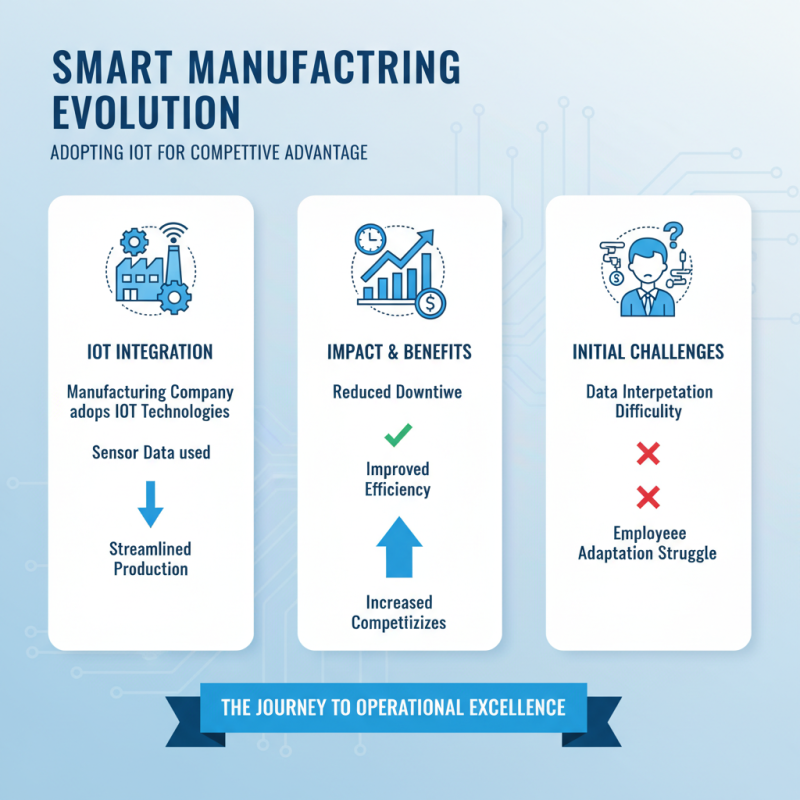

In recent years, many industries have shifted towards integrating advanced solutions to stay competitive. One compelling case is a manufacturing company that adopted IoT technologies. By using sensor data, they streamlined their production line. This led to reduced downtime and improved efficiency. However, they initially faced challenges in data interpretation. Employees struggled with adapting to new processes.

Another example involves a logistics firm. They implemented automation in their warehousing systems. This decision improved order fulfillment rates. Yet, they encountered resistance from staff who feared job loss. Training sessions were crucial to ease these concerns. It revealed a need for constant communication during transitions.

These case studies highlight the importance of thoughtful integration. While technology drives progress, human factors play a vital role. Balancing innovation with employee engagement remains a challenge. Organizations must reflect on their approach to ensure seamless transitions.

The landscape of industrial solutions is rapidly evolving. Businesses must adapt to survive and thrive. Future trends highlight the need for smarter technologies. Automation is becoming commonplace. It streamlines operations and reduces human error. Companies are increasingly relying on data analytics. This allows for better decision-making and forecasting.

Sustainability is another key focus. Firms are seeking eco-friendly practices. This includes using renewable energy sources and reducing waste. Such changes not only enhance corporate responsibility but also appeal to consumers. Yet, many organizations struggle to implement these trends effectively. Transitioning can be challenging and resource-intensive.

Collaboration is crucial for progress. Businesses often need to partner with tech firms or specialists. This ensures they have the right tools and knowledge. However, trust can be an issue. Companies must be open about their goals. Communication is vital. The future of industrial solutions hinges on flexibility and adaptability. Those who embrace change will lead the market.

| Dimension | Description | Impact on Business | Future Trend |

|---|---|---|---|

| Automation | Use of technology to perform tasks with minimal human intervention. | Increases efficiency and reduces labor costs. | Integration of AI and machine learning. |

| Data Analytics | Analyzing data to make informed business decisions. | Helps in identifying trends and improving operational efficiency. | Growth in predictive analytics and real-time data use. |

| Supply Chain Management | Managing the flow of goods and services. | Optimizes logistics and reduces operational costs. | Adoption of blockchain for transparency. |

| Sustainability | Implementing practices that reduce environmental impact. | Attracts eco-conscious consumers and improves brand image. | Shift towards circular economy practices. |

| Collaboration Tools | Tools that enhance teamwork and communication. | Increases productivity and fosters innovation. | Rise of remote collaboration technologies. |

We’re here to help and answer your questions.