In 2023, the manufacturing industries are undergoing a transformative wave of innovations that promise to redefine operational efficiency and productivity. Dr. Emily Carter, a leading expert in advanced manufacturing technologies, has aptly noted, "The integration of digital tools and eco-friendly practices is not just an option; it's a necessity for the survival of manufacturing industries in today’s competitive landscape." This shift towards modernization is not merely a response to external pressures, but a proactive approach that embraces trends such as automation, artificial intelligence, and sustainability.

As we delve into the top 10 innovations shaping the future of manufacturing, it becomes clear that these advancements are closely linked to enhancing production capabilities and reducing environmental impact. From smart factories powered by IoT to the adoption of additive manufacturing techniques, the landscape of manufacturing industries is evolving at an unprecedented pace. The innovations highlighted in this discussion are a testament to the resilience and adaptability of manufacturers as they navigate the challenges and opportunities presented in this era of rapid technological change.

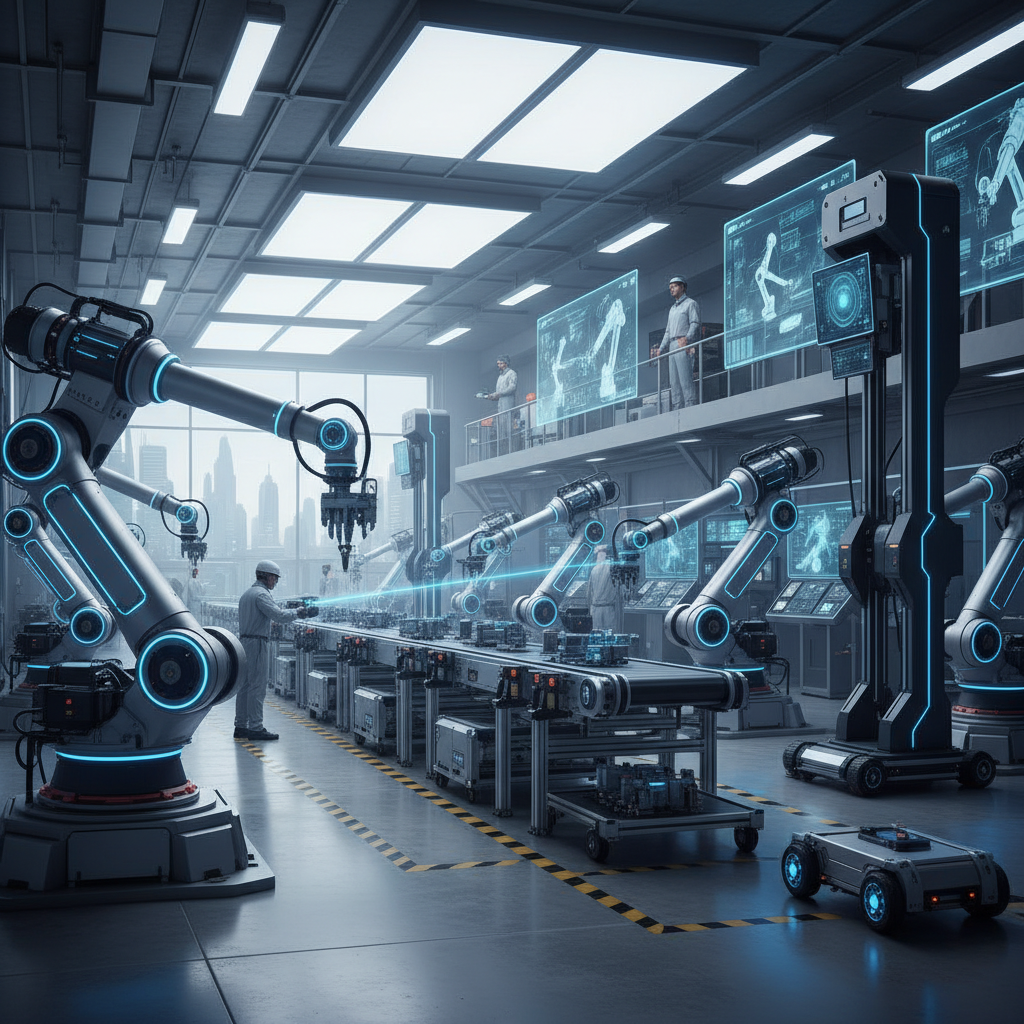

In 2023, innovative robotics has emerged as a game-changer in the manufacturing industry, significantly enhancing

efficiency and productivity. Automation through advanced robotics systems allows manufacturers to streamline operations,

reduce labor costs, and improve quality control. Robots are now capable of performing complex tasks, from assembly to quality inspection,

with precision that surpasses human capabilities. This shift not only speeds up production cycles but also allows human workers to focus on

more strategic roles within the facility.

Tips for integrating robotics into your manufacturing process include starting with a comprehensive needs assessment to identify areas where

automation can have the most impactful results. Implementing collaborative robots, or cobots, can facilitate smoother transitions

in workplaces by working alongside human operators and assisting with repetitive tasks. Additionally, continuous training and upskilling

for your workforce are essential, ensuring that employees are well-equipped to leverage these technological advancements effectively.

Another crucial tip is to monitor and analyze data from robotic systems to optimize performance. By leveraging real-time data analytics,

manufacturers can make informed decisions on maintenance, resource allocation, and process improvements, ultimately leading to sustained increases

in productivity and efficiency across operations. Embracing these innovations

not only enhances competitiveness but also positions manufacturers to adapt to future market demands.

Smart materials are set to revolutionize product design and durability in the manufacturing industry in 2023. As industries increasingly seek sustainability and efficiency, innovations in advanced materials are taking center stage. A significant development is the integration of bio-based and smart textiles, which not only enhance the aesthetic of products but also contribute to environmental conservation. Recent discussions at sessions focused on "Advanced Materials for Sustainable Future" highlighted that incorporating these materials can reduce waste while improving product longevity. For instance, by utilizing fabric innovations anticipated for 2026, manufacturers can benefit from textiles that are not just functional but also biodegradable, aligning with a growing consumer demand for sustainable options.

Moreover, the advancements in nanotechnology and 4D printing are transforming how products are conceived and constructed, allowing for materials that adapt and respond dynamically to environmental changes. Reports indicate that 4D printed smart materials can change their shape or function over time, providing unprecedented flexibility and durability in product design. This capability is particularly beneficial in applications ranging from healthcare to automotive manufacturing, where precision and adaptability are paramount. By leveraging these cutting-edge technologies, manufacturers can enhance efficiency, minimize material waste, and deliver innovative solutions that meet the evolving demands of the market.

In 2022, the artificial intelligence market was valued at $27.92 billion, with projections indicating growth to $35.65 billion by 2030. This trajectory reflects a robust compound annual growth rate (CAGR) of 32.4%, underscoring the increasing reliance on AI-driven strategies across sectors. North America led the market in 2022, commanding a significant 35.6% share, driven by advancements in AI technologies that enhance decision-making and predictive maintenance processes.

Within the manufacturing industry, AI plays a pivotal role in predictive maintenance, utilizing machine learning algorithms and advanced analytics to foresee equipment failures and optimize maintenance schedules. This innovative approach not only minimizes unexpected downtime but also extends asset lifespan and reduces operational costs. According to industry reports, the predictive maintenance market—enhanced by AI—is anticipated to experience substantial growth, indicating a transformative shift in operational efficiency for manufacturing processes by 2032.

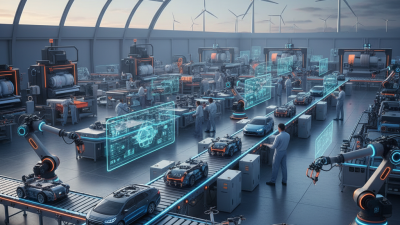

The manufacturing industry is undergoing a significant transformation in 2023, with a prominent focus on sustainable practices. As companies strive to reduce their environmental impact, integrating eco-friendly methods into production processes has become essential for future growth. Sustainable manufacturing not only benefits the planet but also enhances operational efficiency and brand reputation. By adopting renewable energy sources, minimizing waste, and prioritizing sustainable materials, manufacturers can create a lasting positive impact.

Tip: Evaluate your supply chain management to identify areas where eco-friendly materials can replace traditional ones. Not only does this contribute to sustainability, but it can also optimize costs in the long run.

Companies are increasingly leveraging innovation to implement these eco-friendly practices. For instance, incorporating advanced technologies such as AI and IoT can optimize resource use, allowing manufacturers to monitor energy consumption and reduce waste effectively. Additionally, embracing circular economy principles can foster an environment where materials are reused and recycled, further diminishing the manufacturing footprint.

Tip: Consider investing in smart manufacturing technologies that track and report sustainability metrics, helping your business make informed decisions that align with eco-conscious goals.

| Innovation | Description | Impact on Sustainability | Implementation Year |

|---|---|---|---|

| 3D Printing | Additive manufacturing reduces waste by using only the required amount of material. | Less material waste and energy consumption. | 2023 |

| IoT Integration | Using interconnected devices for real-time monitoring of equipment and processes. | Improves efficiency and reduces energy consumption. | 2023 |

| Circular Economy Practices | Reusing materials and products to minimize waste. | Reduces landfill waste and promotes sustainability. | 2023 |

| Smart Sensors | Devices that monitor and manage factory conditions for optimal performance. | Enhances resource management and energy savings. | 2023 |

| Energy-Efficient Technologies | Technologies designed to reduce energy consumption in manufacturing processes. | Lowers carbon footprint and operating costs. | 2023 |

| Green Supply Chains | Incorporating sustainable practices throughout the supply chain. | Reduces environmental impact from sourcing to delivery. | 2023 |

| Biodegradable Materials | Using materials that can break down naturally after use. | Minimizes long-term waste in landfills. | 2023 |

| Virtual Reality Training | Training workers using virtual environments to enhance safety and efficiency. | Reduces accidents and improves workforce competence. | 2023 |

| Advanced Robotics | Utilizing robots for precise manufacturing and reduction of waste. | Enhances production efficiency and reduces material waste. | 2023 |

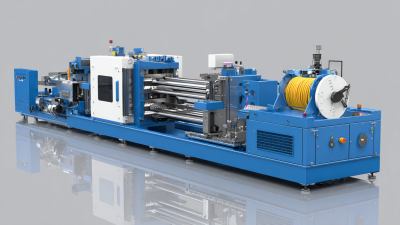

In 2023, the additive manufacturing sector is witnessing unprecedented growth, significantly reshaping the landscape of customization and speed in production. A detailed market analysis projects that the Global 3D Printed Satellite Market is set to reach a valuation of USD 1582.6 million by 2034, with a remarkable compound annual growth rate (CAGR) of 27.23%. This surge underscores the rising demand for advanced manufacturing techniques, enabling tailored solutions that meet specific customer needs across various industries.

Innovations in additive manufacturing are further exemplified by collaborations aimed at enhancing large-format 3D printing technologies. Companies are leveraging pellet-fed 3D printing, showcasing the potential for increased material efficiency and reduced production times. These advancements not only expedite the manufacturing process but also broaden the range of applications, from aerospace to healthcare, illustrating how additive manufacturing is pivotal in driving forward the capabilities of modern industries.

We’re here to help and answer your questions.