In the current landscape of industrial productivity, the relevance of manufacturing applications is more pronounced than ever. According to a report by the World Economic Forum, nearly 80% of manufacturers are expected to increase their investments in digital technologies by 2025, with a significant emphasis on manufacturing applications. These tools are not merely software; they embody strategies that facilitate streamlined operations, enhance quality control, and reduce downtime, ultimately driving business growth.

Additionally, the McKinsey Global Institute reports that companies leveraging advanced manufacturing applications can realize productivity improvements of up to 30%. This shift towards automation and digitalization enables businesses to navigate complexities in supply chain management, meet evolving consumer demands, and maintain competitive advantages in an increasingly globalized market. Consequently, the integration of comprehensive manufacturing applications can lead to significant cost reductions and improved operational efficiency, presenting a compelling case for their adoption across the manufacturing sector.

In today's competitive business landscape, manufacturing applications have emerged as vital tools for enhancing growth and operational efficiency. A report by the National Association of Manufacturers (NAM) highlights that nearly 75% of manufacturers believe that adopting advanced manufacturing technologies significantly improves productivity. This trend underscores the necessity for businesses to integrate applications that streamline workflows, reduce downtime, and optimize resource allocation.

In today's competitive business landscape, manufacturing applications have emerged as vital tools for enhancing growth and operational efficiency. A report by the National Association of Manufacturers (NAM) highlights that nearly 75% of manufacturers believe that adopting advanced manufacturing technologies significantly improves productivity. This trend underscores the necessity for businesses to integrate applications that streamline workflows, reduce downtime, and optimize resource allocation.

Moreover, according to a study by McKinsey, industries that leverage digital manufacturing solutions can experience up to a 30% increase in efficiency and a 20% reduction in operational costs. The shift towards automation and real-time data analytics within manufacturing applications allows companies to respond swiftly to market demands and maintain competitive advantage. As the manufacturing sector continues to evolve, those that embrace these technological advancements will not only enhance their operational capabilities but also ensure sustainable growth in an ever-changing economic environment.

The adoption of manufacturing applications has become a crucial driver for business growth and operational efficiency. Recent statistics highlight that companies integrating these technologies have experienced a remarkable increase in productivity. A recent study revealed that organizations leveraging manufacturing applications have seen productivity gains of up to 25%. This surge is attributed to enhanced processes, streamlined workflows, and reduced downtime, all of which play a significant role in boosting overall efficiency.

Furthermore, the financial impact of adopting manufacturing applications is noteworthy. Businesses that have implemented such technologies report an average revenue growth of 15% over three years. This growth is often linked to improved inventory management and better demand forecasting capabilities, allowing companies to respond swiftly to market changes. As manufacturers continue to embrace digital solutions, they not only enhance their competitiveness but also create opportunities for innovation, paving the way for sustained growth in an increasingly demanding marketplace.

Manufacturing applications play a pivotal role in enhancing business growth and operational efficiency. One of the key features that drive this efficiency is real-time data tracking. By utilizing advanced sensors and IoT technologies, manufacturers can monitor production processes, equipment performance, and inventory levels in real time. This instantaneous access to data allows for quicker decision-making and troubleshooting, reducing downtime and minimizing waste, which ultimately leads to improved productivity.

Another important feature is automation capabilities. Modern manufacturing applications incorporate automation tools that streamline repetitive tasks and workflows, such as inventory management and order processing. By automating these areas, businesses can reduce human error, free up valuable labor resources, and ensure consistent quality in their products. Additionally, robust analytics tools embedded within these applications provide valuable insights into operational performance, helping businesses identify areas for improvement and optimize processes effectively. Through the integration of these features, manufacturing applications serve as essential assets for fostering efficiency and driving business success.

| Feature | Description | Impact on Efficiency |

|---|---|---|

| Real-time Data Analytics | Allows manufacturers to make informed decisions based on current data. | Increases operational agility and responsiveness to market changes. |

| Supply Chain Management | Streamlines procurement, logistics, and inventory management processes. | Reduces lead times and ensures timely delivery of products. |

| Quality Control Automation | Automates inspection and testing processes to maintain product standards. | Minimizes defects and reduces waste, enhancing product reliability. |

| Predictive Maintenance | Uses sensor data and algorithms to predict equipment failures. | Boosts equipment uptime and extends machinery life. |

| Integration with IoT | Connects machines and devices for seamless data exchange. | Improves synchronization across production processes. |

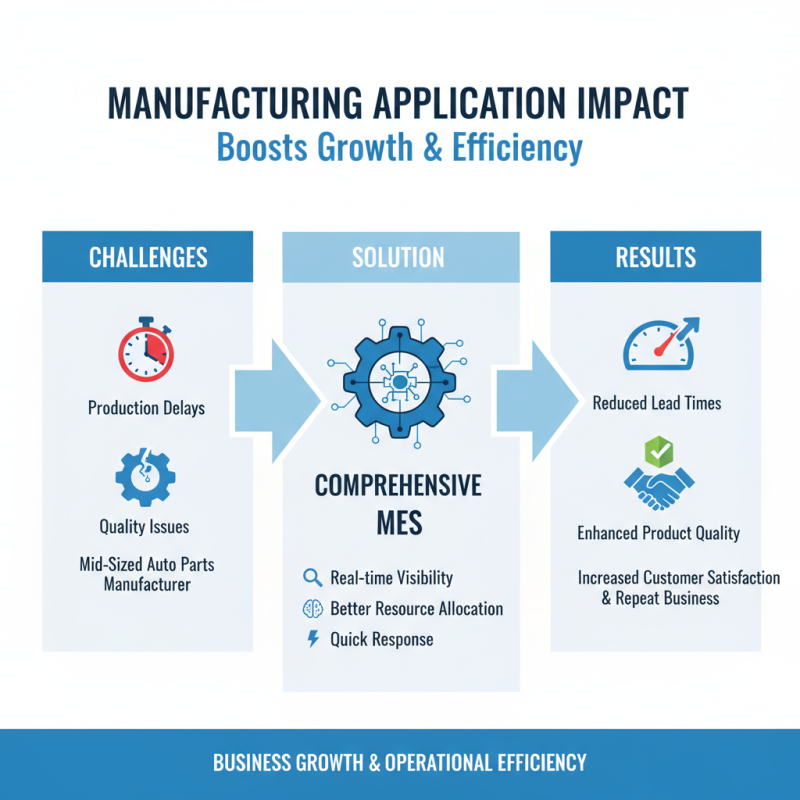

The successful implementation of manufacturing applications can significantly impact business growth and operational efficiency. Take, for example, a mid-sized automotive parts manufacturer that faced challenges with production delays and quality control issues. By adopting a comprehensive manufacturing execution system (MES), the company improved real-time visibility into its production processes. This integration allowed for better resource allocation and quicker response times to anomalies on the shop floor. As a result, the manufacturer not only reduced lead times but also enhanced product quality, ultimately leading to increased customer satisfaction and repeat business.

Another compelling case study comes from a textiles company that utilized data analytics to streamline its supply chain management. By leveraging predictive analytics software, the firm was able to forecast demand more accurately and manage inventory levels efficiently. This proactive approach minimized excess stock and reduced holding costs, allowing the company to maximize profit margins. Furthermore, the insights gained from the analytics helped the business negotiate better terms with suppliers, cementing stronger relationships while maintaining flexibility in its supply chain. Through these case studies, it is evident that manufacturing applications are not merely tools but essential components for fostering competitive advantage and driving continuous improvement in the industry.

The future of manufacturing applications is poised to heavily impact business growth and operational efficiency. As technological advancements continue to accelerate, industries are witnessing a significant transformation characterized by the integration of smart technologies such as IoT, artificial intelligence, and data analytics. These innovations enable companies to optimize their production processes, reduce waste, and enhance product quality. For instance, predictive maintenance powered by AI can anticipate equipment failures, minimizing downtime and leading to cost savings which ultimately contribute to a company’s bottom line.

Additionally, as manufacturers increasingly adopt cloud-based solutions, collaboration across the supply chain is steadily improving. Real-time data sharing among stakeholders allows for more agile decision-making and responsiveness to market changes. With the rise of automation and robotics, productivity can be expected to soar, freeing human workers to focus on more strategic tasks. This shift not only enhances operational performance but also leads to improved employee satisfaction, as they engage in more meaningful and less monotonous work. Overall, these trends indicate a future where manufacturing applications will be crucial in defining the competitive landscape and driving sustainable growth in the industry.

We’re here to help and answer your questions.