Manufacturing industries play a crucial role in the backbone of modern economies, driving innovation, creating jobs, and facilitating trade. They encompass a wide range of processes and products, from raw material extraction to the final assembly of consumer goods. Understanding what manufacturing industries entail is essential for grasping the dynamics of economic development and technological advancements. In this comprehensive guide, we will delve into the key concepts that define manufacturing industries, revealing their complexities and significance in today's world.

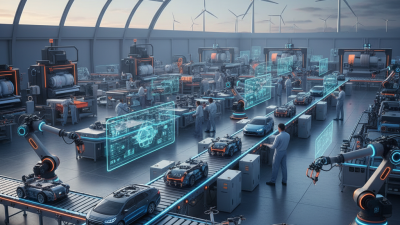

As we explore the diverse facets of manufacturing industries, we will examine their various classifications, ranging from heavy industries to light manufacturing. Each sector has unique characteristics that influence production methods, labor requirements, and environmental impacts. We will also look into current trends shaping the industry, such as automation, sustainable practices, and the rise of smart manufacturing technologies. By providing a thorough overview of these vital concepts, this guide aims to equip readers with a clearer understanding of how manufacturing industries operate and their pivotal role in global economic landscapes.

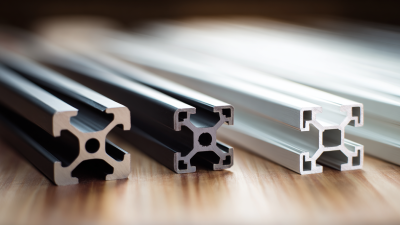

Manufacturing industries encompass a wide range of processes and techniques used to transform raw materials into finished goods. At its core, manufacturing involves the conversion of materials into products that can be sold to consumers, businesses, or other entities. This sector is vital for economic development, as it not only creates jobs but also contributes significantly to gross domestic product (GDP). Understanding the definition of manufacturing industries involves recognizing their complexities, including various types, such as heavy and light manufacturing, and the different technologies employed, from traditional methods to advanced automation.

Tips for aspiring entrepreneurs in manufacturing include focusing on quality control and sustainable practices. Emphasizing quality ensures that the products meet customer expectations and industry standards, which is crucial for building brand reputation. Additionally, integrating sustainable practices into manufacturing processes can lead to significant cost savings and appeal to environmentally conscious consumers. Embracing innovation and technology is also essential; this can involve adopting new machinery or digitizing operations to improve efficiency and reduce waste.

It's important to stay informed about market trends and consumer preferences within the manufacturing sector. Engaging with industry networks and participating in trade shows can provide valuable insights and help businesses adapt to changes. Building strong relationships with suppliers can also lead to more reliable sourcing of raw materials and enhance overall production efficiency.

| Category | Definition | Scope | Key Processes |

|---|---|---|---|

| Automotive | Industry focused on the design, development, manufacturing, marketing, and selling of motor vehicles. | Includes passenger cars, trucks, and motorcycles, alongside their components. | Assembly line production, quality control, and supply chain management. |

| Electronics | Production of electronic devices and components such as semiconductors and circuit boards. | Covers consumer electronics, industrial appliances, and telecommunications gear. | Fabrication, assembly, and testing processes. |

| Textiles | Involves the production of fiber, yarn, and fabric to create clothing and home textiles. | Includes clothing, upholstery, and industrial textiles. | Spinning, weaving, dyeing, and finishing processes. |

| Food and Beverage | Manufacturing of food products and beverages from raw materials. | Includes processed foods, dairy, meats, and soft drinks. | Processing, packaging, and quality assurance. |

| Pharmaceuticals | Development and production of medications and health products. | Encompasses prescription drugs, over-the-counter medications, and vaccines. | Research, formulation, and compliance testing. |

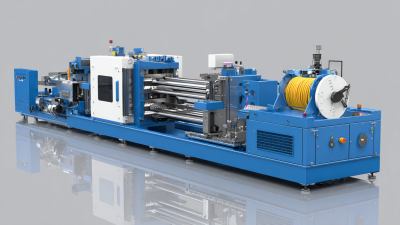

Manufacturing industries encompass a broad array of processes that transform raw materials into finished goods, employing various techniques to increase efficiency and quality. One prominent method is assembly line production, which allows for the mass production of items by breaking down the manufacturing process into smaller, repeatable tasks. This approach significantly enhances productivity and reduces labor costs, making it a staple in the automotive and electronics sectors.

Another critical manufacturing technique is additive manufacturing, commonly known as 3D printing. This innovative process enables the creation of complex structures layer by layer, offering unprecedented design flexibility. Industries such as aerospace and healthcare have leveraged this technology to produce customized parts and prototypes quickly, adapting to changes in demand and optimizing material use. Each manufacturing process plays a vital role in shaping the industry, highlighting the diverse techniques that drive advancements in production and design capabilities.

The manufacturing sector is a critical component of the global economy, encompassing a diverse range of industries that produce goods through various processes. Key players in this field include manufacturers, suppliers, and consumers, each contributing to the production and distribution of products. In recent years, the sector has faced significant challenges and opportunities, particularly as governments across the globe implement policies to revive domestic production and encourage innovation.

Stakeholders such as technology firms, regulatory bodies, and investors play a *pivotal* role in shaping the landscape of manufacturing. As seen in the discourse around semiconductors, the imposition of tariffs and the push for local manufacturing capabilities reflect the intricate balance between global trade dynamics and national interests. Furthermore, the rising demand for specialty chemicals, particularly in the fragrance industry, underscores the importance of adaptability and forward-thinking strategies among manufacturers to remain competitive and meet evolving consumer needs.

As the market for fragrance chemicals is projected to grow significantly over the coming years, manufacturers must collaborate closely with stakeholders to ensure they can effectively navigate these changes.

The impact of technology and innovation on manufacturing efficiency is profound and multifaceted, shaping the landscape of production processes across various industries. Modern manufacturing increasingly relies on advanced technologies such as automation, artificial intelligence, and the Internet of Things (IoT). These innovations streamline operations, reduce human error, and enhance precision, leading to faster production cycles and lower operational costs. For instance, automated machinery can operate consistently at high speeds, significantly outperforming manual labor while minimizing waste and resource consumption.

Moreover, integrating data analytics into manufacturing processes allows companies to make informed decisions based on real-time insights. By leveraging big data, manufacturers can optimize supply chains, predict equipment failures, and refine inventory management. This proactive approach not only improves product quality but also increases responsiveness to market demands. As manufacturers continue to adopt cutting-edge technologies, the overall efficiency of production systems will likely improve, driving competitiveness in an ever-evolving global marketplace.

The manufacturing industry is undergoing significant transformations driven by various challenges and emerging trends. One major challenge is the growing skill gap in the workforce. According to a report by the Manufacturing Institute, nearly 2.1 million manufacturing jobs are expected to go unfilled by 2030 due to workforce shortages. This gap not only hampers production capabilities but also affects innovation and operational efficiency.

Moreover, sustainability practices are increasingly shaping the industry's future. A study by McKinsey indicated that up to 70% of manufacturing executives see sustainability as a critical driver for competitiveness and profitability. Companies are adopting advanced technologies like IoT and AI to improve energy efficiency and reduce waste, aligning themselves with regulatory standards and consumer expectations. As manufacturers embrace these trends, they are not just enhancing their operational practices, but also paving the way for a more sustainable and resilient industry.

We’re here to help and answer your questions.