In today's fast-paced industrial landscape, optimizing manufacturing applications is essential for success. John Smith, a renowned expert in manufacturing technology, states, "Efficiency drives profitability in manufacturing applications." His insight highlights the critical need for effective strategies in the sector.

Manufacturing applications encompass various processes, tools, and systems. Businesses must examine their current practices to identify inefficiencies. Perhaps outdated machinery or software holds them back. The focus should not only be on technology but also on how teams work together. Poor communication affects productivity significantly.

As the industry evolves, companies should embrace innovation while reflecting on their practices. There's always room for improvement in manufacturing applications. Identifying bottlenecks might reveal surprising insights. Businesses that are willing to adapt and enhance their strategies will lead the way.

Assessing current manufacturing processes is crucial for identifying efficiency gaps. Recent studies indicate that 70% of manufacturing companies face challenges in workflow optimization. By analyzing production lines, organizations can uncover bottlenecks that slow down operations. Common issues include machine downtime and unproductive staff time. These factors can lead to up to a 20% reduction in overall output.

In addition, workforce training plays a pivotal role in efficiency. According to industry reports, only 30% of employees feel equipped to handle new technologies. This creates a gap in performance. Organizations must actively invest in training programs to bridge this divide. Providing hands-on training can enhance skills and reduce error rates, directly impacting productivity.

Moreover, many businesses overlook the importance of real-time data monitoring. Approximately 65% of manufacturers do not use data analytics effectively. Without real-time insights, it’s challenging to make informed decisions. This lack of visibility can exacerbate inefficiencies. Fostering a data-driven culture can empower teams to respond quickly to operational issues. Identifying these inefficiencies requires ongoing assessment and a willingness to adapt practices for better results.

| Process Type | Efficiency Rate (%) | Downtime (Hours/Week) | Bottleneck Identified | Improvement Action Suggested |

|---|---|---|---|---|

| Assembly Line | 78 | 10 | Material Supply Delay | Automate Inventory Management |

| Quality Inspection | 85 | 6 | Inconsistent Testing Methods | Standardize Testing Procedures |

| Packaging | 90 | 4 | Manual Handling | Implement Conveyor System |

| Machining | 82 | 8 | Tool Change Over Time | Invest in Quick Change Tooling |

| Logistics | 75 | 12 | Route Optimization | Use Route Planning Software |

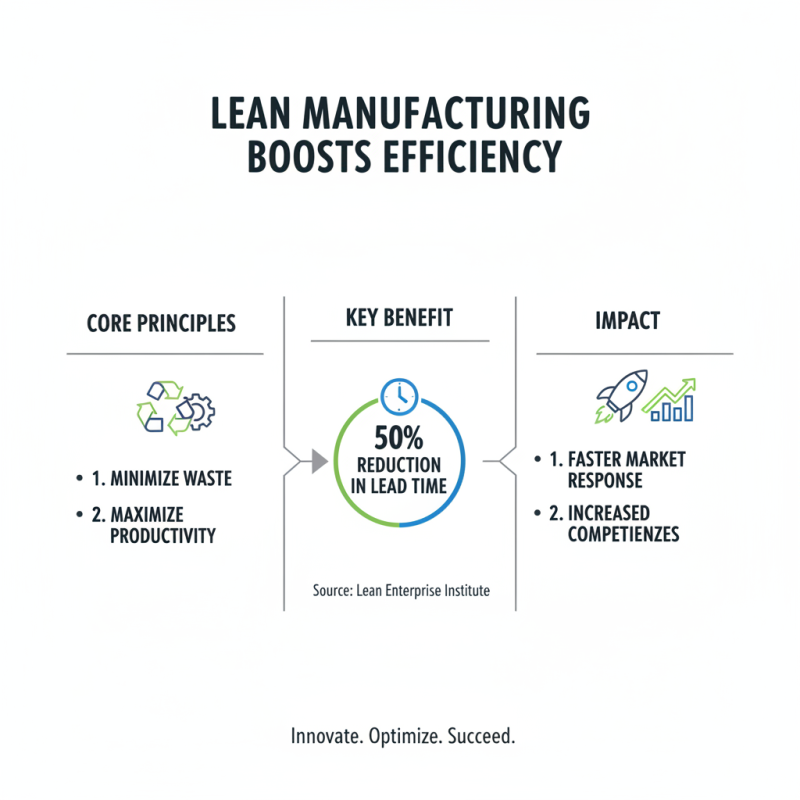

Implementing lean manufacturing principles can significantly boost the efficiency of manufacturing applications. Lean practices focus on minimizing waste while maximizing productivity. According to a report from the Lean Enterprise Institute, organizations that adopt lean methods can reduce lead time by up to 50%. This is critical in today's fast-paced market, where responsiveness is key.

One key aspect of lean manufacturing is value stream mapping. This technique identifies all the actions required to bring a product from concept to delivery. By analyzing each step, manufacturers can pinpoint inefficiencies. Studies show that companies utilizing value stream mapping have increased their process efficiency by 30%. However, some firms struggle with this implementation. It requires a cultural shift, which can be challenging.

Another important principle is continuous improvement, or kaizen. Engaging employees at all levels can foster innovation. Regular feedback loops can lead to small, incremental changes that accumulate over time. Yet, teams often face resistance to change. Overcoming this requires patience and perseverance. Ultimately, implementing lean manufacturing is not just about tools but also about transforming mindsets across the organization.

In today's fast-paced manufacturing landscape, automation and technology play pivotal roles in enhancing productivity. Companies are increasingly adopting robots and automated systems to streamline operations. This shift not only speeds up production but also minimizes human errors. Automated machinery can run continuously, boosting output levels significantly. However, implementing these technologies requires careful planning and training for workers. Not every employee is comfortable with advanced systems. This can lead to resistance or mistakes during the transition.

Moreover, data analytics is another critical area to explore. Utilizing real-time data on production lines can help identify bottlenecks and inefficiencies. You may find that certain machines are underperforming. Addressing these issues can lead to a more fluid operation. However, it's essential to remember that technology can fail or provide misleading information. Relying solely on automated systems without human oversight may create challenges. Balancing technology with human insight often leads to the most productive outcomes in manufacturing.

Analyzing data and metrics is vital for manufacturing efficiency. It allows businesses to identify bottlenecks and areas for improvement. A simple analysis of production cycles can reveal delays and inefficiencies. For instance, measuring the time taken for each stage can highlight slow processes. Small changes in these areas can lead to significant efficiency gains.

Continuous improvement relies on regular monitoring of key performance indicators. Metrics like overall equipment effectiveness (OEE) and first-pass yield are crucial. However, gathering too much data can be overwhelming. Companies often focus on the wrong metrics, which may lead to misguided efforts. Regular reflection is needed; teams should evaluate what data truly drives improvement.

Engagement from all levels of the organization is essential. Employees working on the floor can provide valuable insights. Their experiences often reveal issues not visible in data alone. Ignoring this feedback can hinder progress. Thus, combining quantitative and qualitative data creates a clearer picture of operations. Adapting to these insights fosters a culture of innovation.

Training the workforce is crucial for enhancing manufacturing efficiency. Recent studies show that companies investing in employee training can see a 24% increase in productivity. Training programs improve skills and encourage a culture of continuous improvement. Workers equipped with the right tools and knowledge can make better decisions on the floor.

However, the effectiveness of training often faces challenges. Many manufacturers report that they struggle to align training with actual production needs. A survey revealed that 60% of workers feel training is outdated or irrelevant. To combat this, organizations need to adopt a more hands-on approach. Real-time training during operational shifts can bridge the gap between theory and practice.

Moreover, regular feedback loops can significantly enhance training effectiveness. Engaging employees in discussions about their experiences can reveal gaps in training content. Actively involving workers in shaping their training ensures they feel valued. It can lead to a more motivated workforce, fostering a sense of ownership and accountability. Balancing skill development with actual job demands remains a work in progress.

We’re here to help and answer your questions.