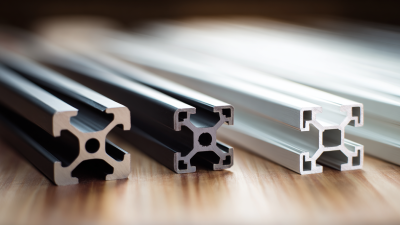

In the realm of contemporary construction, efficiency, durability, and design flexibility are paramount. Among the various materials that have revolutionized building practices, standard aluminium profiles stand out as an indispensable resource. The versatility of these profiles, coupled with their lightweight and corrosion-resistant properties, make them a preferred choice for architects and builders alike. As construction projects grow in complexity and scale, the demand for reliable and standardized components has never been higher, and standard aluminium profiles have risen to meet this challenge.

Standard aluminium profiles offer a myriad of advantages, including ease of fabrication, cost-effectiveness, and sustainability. They are integral in everything from structural frameworks to intricate architectural designs, allowing for seamless integration of aesthetics and functionality. The inherent strength of aluminium ensures that constructions can withstand the test of time while maintaining their visual appeal. As we delve deeper into the top ten reasons why standard aluminium profiles are essential for modern construction projects, it becomes clear that these components not only enhance the efficiency of building processes but also contribute significantly to the overall quality and longevity of construction endeavors.

Standard aluminium profiles have become indispensable in modern architectural design due to their remarkable versatility. A recent report from the Aluminium Association highlights that the global market for aluminium in architectural applications is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026. This growth reflects the increasing demand for materials that offer both aesthetic appeal and functional reliability, making aluminium profiles a prime choice for architects and builders.

One of the key advantages of standard aluminium profiles is their ability to be easily adapted for various applications, from window frames to structural supports. According to a study by the International Aluminium Institute, approximately 40% of aluminium production is utilized in building and construction, emphasizing the material's role in sustainable design. With their lightweight nature paired with high strength, aluminium profiles enable innovative designs that can enhance the architectural aesthetics while maintaining structural integrity. This versatility allows for the incorporation of unique architectural features and modern designs that are both striking and efficient.

Aluminium profiles have become a cornerstone in modern construction, significantly enhancing structural integrity across various applications. According to a report by the Aluminium Association, the use of aluminium in construction has grown by over 20% in the past decade, attributed to its lightweight properties and high resistance to corrosion. These profiles provide essential support in structures ranging from residential buildings to large commercial complexes, where safety and durability are paramount.

Moreover, the adaptability of aluminium profiles allows for innovative designs that can meet specific engineering demands. The World Aluminium report emphasizes that incorporating these profiles into a construction project can reduce material costs by up to 15%, while simultaneously increasing the overall strength of the structure. This effectiveness is particularly vital in seismic zones, where lighter materials can minimize stress during earthquakes while ensuring compliance with stringent building codes. As the construction industry continues to evolve, the role of standard aluminium profiles will remain critical in achieving enhanced safety and performance in modern infrastructures.

The cost-effectiveness of using standard aluminium profiles in building materials is increasingly recognized in modern construction projects. Standard aluminium profiles offer a streamlined solution, simplifying the construction process while reducing material waste. By utilizing profiles that are pre-engineered and widely available, contractors can lower procurement costs and minimize lead times. This efficiency not only translates to financial savings but also allows projects to adhere to tight schedules, which is crucial in today’s fast-paced construction environment.

Moreover, the durability and lightweight nature of aluminium contribute to lower overall project costs. Standard aluminium profiles are resistant to corrosion and require minimal maintenance, extending the lifespan of structures and reducing long-term expenses related to repairs or replacements. Additionally, their ease of installation means that labor costs can also be kept in check. As builders increasingly seek sustainable options, the recyclability of aluminium enhances its appeal, further solidifying its position as a cost-effective choice in modern construction projects.

Sustainability has become a cornerstone in modern construction, and aluminium plays a pivotal role in this transformation. With its inherent properties—lightweight, strong, and recyclable—aluminium presents a distinct advantage over traditional building materials.

The global shift towards green building practices is evident in various regions, including Israel, which has embraced innovative designs and energy-efficient technologies to promote eco-friendly construction.

The rise in the demand for aluminium solutions is supported by projections indicating significant growth in the aluminium sheet market, reflecting a broader trend toward sustainable materials in the construction sector.

Companies like Taural India are leading the way by incorporating low-carbon aluminium into their production processes, further enhancing the environmental benefits associated with this versatile metal.

The emphasis on sustainable materials not only aids in reducing carbon footprints but also aligns with the increasing regulatory demands for eco-friendliness in modern infrastructure projects.

As the construction industry progresses into an era defined by sustainability, aluminium stands out as a key component, revolutionizing how buildings are designed, constructed, and maintained for future generations.

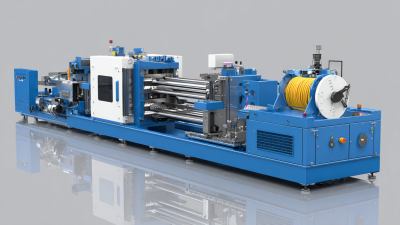

The use of pre-manufactured aluminum solutions is revolutionizing the way construction projects are executed. Streamlining construction processes has become a necessity in today's fast-paced environment, and standard aluminum profiles play a crucial role in achieving this goal. By opting for pre-manufactured components, builders can significantly reduce on-site labor time and enhance efficiency. These profiles, designed for quick assembly, allow construction teams to expedite their projects while maintaining high-quality standards.

Moreover, the consistency and precision of aluminum profiles minimize the likelihood of errors during the construction phase. When components are fabricated off-site in controlled conditions, they benefit from rigorous quality control processes. This ensures that the profiles meet specific measurements and standards, ultimately resulting in a smoother assembly process on-site. By integrating these pre-manufactured aluminum solutions, construction companies can streamline logistics, reduce waste, and improve overall project timelines, making them indispensable in modern construction projects.

We’re here to help and answer your questions.