Aluminium extrusion sections have emerged as a pivotal component in various industries, from construction to automotive, owing to their versatility and lightweight characteristics. As we look toward 2025, the trends surrounding these materials are expected to evolve, driven by advancements in technology and increasing environmental awareness. Industry expert Dr. Emily Carter, a leading researcher in materials engineering, emphasizes the importance of these trends, stating, "The future of aluminium extrusion sections lies in their adaptability to new applications and sustainable practices that cater to a greener economy."

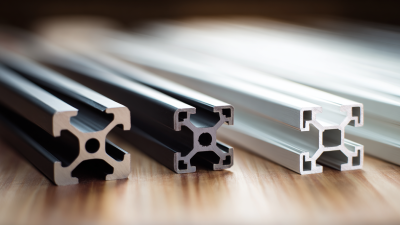

The uses of aluminium extrusion sections are vast, ranging from structural frameworks to intricate designs that enhance aesthetic appeal. As we investigate the growing applications, it is crucial to recognize the benefits these materials bring to manufacturers and consumers alike. With properties that allow for easy customization and high strength-to-weight ratios, they not only reduce the overall carbon footprint but also contribute to cost savings over time. This makes aluminium extrusion sections an integral part of modern manufacturing processes and architectural designs, promising a bright outlook for the coming years.

In this outline, we will explore the top trends in aluminium extrusion sections for 2025, highlighting their diverse uses and the long-term benefits they offer to various sectors.

In 2025, the aluminium extrusion industry is poised for significant evolution, driven by advancements in technology and shifting market demands. With a projected growth rate of 5.4% annually, the global aluminium extrusion market is expected to reach approximately $65 billion by 2025, according to a recent report from industry analysts. This growth is fueled by increasing applications across various sectors, including construction, automotive, and aerospace, where lightweight and durable materials are essential for enhancing energy efficiency and performance.

Key trends in aluminium extrusion sections in 2025 will include a greater focus on sustainability and circular economy practices. The industry is seeing a push towards using recycled aluminium, with estimates suggesting that recycled aluminium uses 95% less energy compared to primary production. This shift not only reduces the carbon footprint associated with aluminium production but also meets the rising consumer demand for environmentally friendly materials. Moreover, innovations in design technology, such as 3D modelling and simulation, are enabling manufacturers to create complex and highly customized extrusion sections that meet specific application needs efficiently.

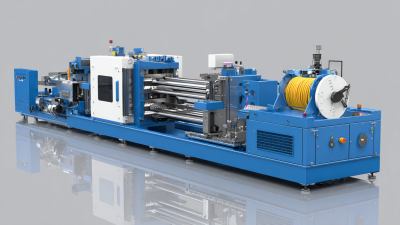

Additionally, the integration of smart manufacturing techniques is set to transform aluminium fabrication processes, enhancing precision and reducing waste. Industry experts predict that the adoption of automation and AI will streamline production, leading to higher quality and shorter lead times. As aluminium extrusion sections become increasingly tailored to diverse industries' requirements, their versatility and efficiency are expected to make them a cornerstone of modern manufacturing and construction initiatives in 2025.

The aluminium extrusion industry is witnessing transformative trends that are reshaping its landscape. As we move towards 2025, sustainability remains at the forefront. According to a recent report by the Aluminium Association, the demand for recyclable materials is projected to rise by 30% over the next five years. This shift not only helps in reducing carbon footprints but also aligns with global initiatives aimed at minimizing environmental impact.

Technological advancements are also driving changes. The integration of automation and smart manufacturing in extrusion processes is expected to enhance efficiency, resulting in cost savings and improved production timelines. A survey by the International Aluminium Institute indicates that 65% of companies are investing in digital technologies to optimize their operations. The use of data analytics is empowering firms to streamline their manufacturing processes and reduce waste significantly.

Tips: To stay competitive, businesses should prioritize investment in sustainable practices and explore the advantages of advanced technologies. Regularly attending industry seminars and workshops can provide insights into emerging trends, helping companies adapt to shifting market demands. Emphasizing innovation while being mindful of environmental responsibilities is key to thriving in the evolving aluminium extrusion sector.

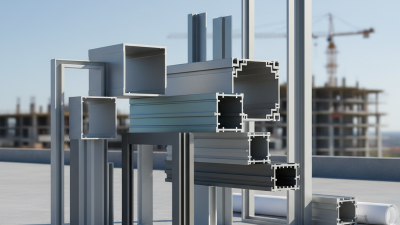

Aluminium extrusion sections are poised to play a pivotal role in various industries in 2025, thanks to their versatility and adaptability. These sections are critical in the construction sector, where they are utilized for window frames, curtain walls, and structural support systems. The lightweight nature of aluminium, combined with its strength and corrosion resistance, makes it an ideal choice for architects and builders aiming for both aesthetic appeal and durability. Furthermore, the ability to create custom profiles means that designers can achieve specific shapes and functionalities tailored to individual projects.

In the automotive and aerospace industries, aluminium extrusion sections are increasingly being adopted for components that require both weight reduction and high-performance capabilities. The growing emphasis on fuel efficiency and sustainability drives the demand for lightweight materials, allowing manufacturers to improve energy economy without compromising safety. Moreover, in the electronics sector, extruded aluminium is frequently used for heat sinks and housings, benefiting from its excellent thermal conductivity and ease of fabrication. As these sectors evolve, the multifaceted applications of aluminium extrusion sections will undoubtedly expand, showcasing their importance in innovation and design.

Aluminium extrusion sections offer numerous benefits that make them an ideal choice for various industries. One of the primary advantages is their lightweight nature, which significantly reduces the overall weight of structures and components, leading to improved energy efficiency in transportation and construction applications. The high strength-to-weight ratio of aluminium allows for the design of robust structures without compromising on performance, making it an invaluable material for sectors like aerospace, automotive, and construction.

Moreover, aluminium extrusion sections boast excellent corrosion resistance, providing longevity and durability in diverse environments. This characteristic reduces maintenance costs and the need for frequent replacements, which can be a significant expense in industries that require long-lasting solutions. Additionally, the versatility of aluminium allows for a wide range of designs, enabling manufacturers to create custom shapes and size specifications tailored to specific applications. This adaptability not only widens the scope for innovation but also ensures that industries can maximize the functionality of their products while maintaining aesthetic appeal.

Aluminium extrusion technology is on the brink of transformation as new innovations emerge that promise to enhance efficiency and functionality. In 2025, we expect to see a significant shift towards smart extrusion techniques, integrating IoT and AI to monitor and optimize the extrusion process in real-time. This will not only improve the precision of dimensions but also reduce waste by ensuring that every part produced meets specific standards. Such advancements will cater to the growing demand for lightweight yet durable materials in industries ranging from automotive to construction.

Tips for manufacturers looking to adopt these new technologies include investing in training for staff on the latest extrusion technologies and software. Staying updated with research and development in the field can also provide valuable insights into the most efficient practices. Additionally, collaborating with tech companies can enhance capability in integrating automated solutions, leading to streamlined production processes that are more sustainable.

As the designs of aluminium extrusions evolve, the focus will also shift towards achieving enhanced aesthetic appeal alongside functional benefits. This dual approach means that designers will need to balance structural integrity with innovation, creating products that aren't just strong but visually attractive as well. The melding of design and functionality will open new avenues for architects and engineers, enabling them to push the boundaries of traditional applications in the coming years.

We’re here to help and answer your questions.