In the rapidly evolving landscape of automation machinery manufacturing, staying informed about the latest trends is crucial for industry players seeking to maintain a competitive edge. According to a recent report by MarketsandMarkets, the global automation machinery market is projected to grow from USD 180 billion in 2022 to USD 280 billion by 2027, reflecting a compound annual growth rate (CAGR) of 9.1%. This remarkable growth underscores the increasing reliance on automation technologies across various sectors, highlighting the need for companies to adapt and innovate.

Industry expert Dr. Emily Carter, a leading authority in automation technologies, once stated, "Embracing the latest trends in automation machinery is not just an option but a necessity for manufacturers aiming to thrive in this fast-paced environment." Her insights resonate with the overarching theme of continuous improvement and smart manufacturing, as companies leverage advanced technologies such as AI, IoT, and robotics to enhance productivity and efficiency.

As we delve into the top ten trends shaping the automation machinery manufacturing landscape, it is essential to recognize the interplay of factors driving these changes. From sustainability initiatives to the integration of smart devices, understanding these trends will empower manufacturers to make informed decisions and optimize their operations for better performance in an increasingly automated world.

The rise of artificial intelligence (AI) and machine learning (ML) in the automation machinery sector is revolutionizing the way manufacturers operate. According to a report by McKinsey & Company, AI has the potential to deliver an additional economic value of $13 trillion globally by 2030, fundamentally transforming industries, including manufacturing. Automation machinery is increasingly incorporating AI-driven systems that enable predictive maintenance, improving efficiency and reducing downtime. By leveraging real-time data analytics, machines can predict failures before they occur, leading to a significant decrease in operational costs.

Moreover, the integration of machine learning algorithms allows for adaptive manufacturing processes that continuously improve based on historical performance data. A study from the International Data Corporation (IDC) highlights that 75% of businesses will be using AI in their operations by 2024, driving a paradigm shift towards smart manufacturing. This shift not only enhances productivity but also supports sustainability goals by optimizing resource consumption and reducing waste. As manufacturers harness the power of AI and ML, the future of automation machinery looks promising, with intelligent systems that are capable of adapting and evolving in response to dynamic market demands.

| Trend | Description | Impact on Industry | Adoption Rate (%) |

|---|---|---|---|

| AI-Powered Predictive Maintenance | Utilization of AI to predict equipment failures before they occur. | Increases uptime and reduces maintenance costs. | 65% |

| Robotic Process Automation (RPA) | Automation of routine tasks using bots. | Enhances operational efficiency and reduces human error. | 70% |

| AI-Driven Quality Control | Using AI to improve quality control processes in manufacturing. | Reduces defects and enhances product quality. | 60% |

| Smart Manufacturing | Integration of IoT and AI for optimized production processes. | Increases efficiency and lowers operational costs. | 75% |

| Digital Twins | Creation of digital replicas of physical machinery for simulation. | Allows for better analysis and performance improvement. | 55% |

| AI in Supply Chain Management | Leveraging AI to optimize supply chain operations. | Improves responsiveness and reduces costs. | 67% |

| Autonomous Machinery | Machines that operate without human intervention. | Increases safety and efficiency in hazardous environments. | 50% |

| AI-Enhanced Decision Making | Support for decision-making processes using AI analytics. | Leads to more informed and faster decisions. | 62% |

| AI-Optimized Training Programs | Tailored employee training programs driven by AI insights. | Enhances employee skills and productivity. | 58% |

| Edge Computing in Automation | Processing data near the source to improve response times. | Reduces latency and bandwidth use. | 54% |

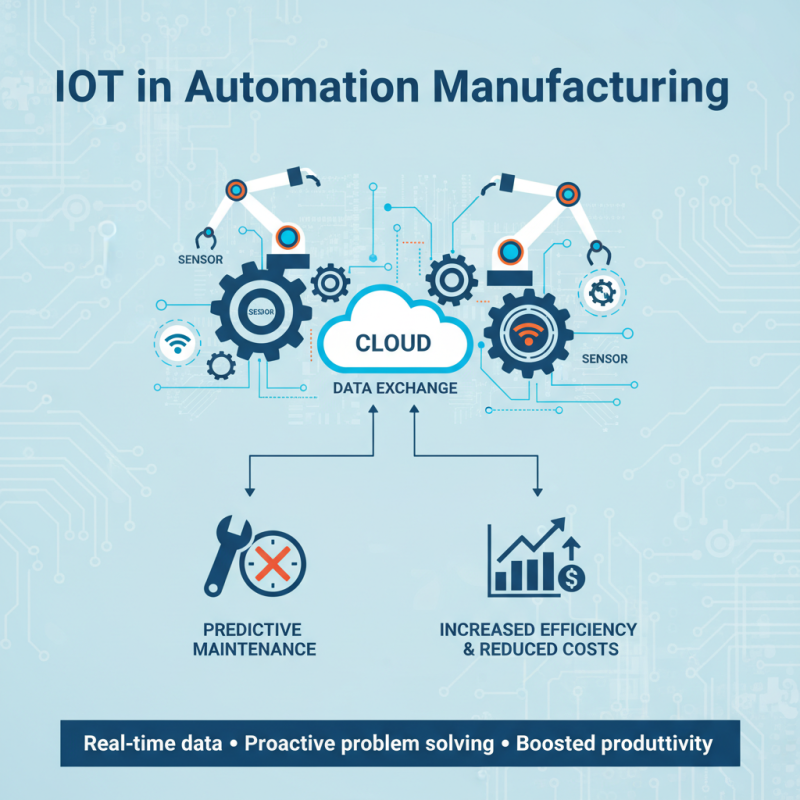

The integration of the Internet of Things (IoT) in automation machinery manufacturing is transforming how machines operate and interact with each other. By embedding sensors and communication capabilities into machinery, manufacturers can achieve enhanced connectivity, allowing for real-time data exchange and analysis. This integration facilitates predictive maintenance, meaning potential issues can be detected and addressed before they lead to costly downtime. As a result, manufacturers are seeing improvements in operational efficiency and reduced maintenance costs, contributing to overall productivity.

Furthermore, the real-time data generated from IoT-enabled machines provides insights into performance metrics, enabling manufacturers to optimize processes continuously. This capability empowers decision-makers to respond swiftly to changing conditions on the production floor, improving supply chain responsiveness. Additionally, with centralized data management, industries can implement advanced analytics and machine learning algorithms to identify patterns and drive further innovations in automation, ensuring they remain competitive in a rapidly evolving landscape. This focus on enhanced machine connectivity not only streamlines operations but also fosters an environment ripe for innovation, setting the stage for future advancements in manufacturing technology.

The recent advancements in robotics have significantly transformed the landscape of manufacturing processes. With the integration of artificial intelligence, machines are now capable of performing complex tasks that were once exclusively handled by humans. This shift not only enhances precision and efficiency on the production floor but also allows for greater flexibility in manufacturing operations.

Robots equipped with advanced sensors and machine learning algorithms can adapt to changes in their environment, enabling a more responsive approach to manufacturing.

Furthermore, the role of collaborative robots, or cobots, has become increasingly prominent. These robots are designed to work alongside human workers, complementing their skills and increasing overall productivity. By taking on repetitive and hazardous tasks, cobots contribute to a safer work environment while allowing human employees to focus on more strategic activities. This collaboration between humans and robots exemplifies a future where automation not only streamlines processes but also empowers the workforce, creating a synergy that drives innovation in manufacturing.

Sustainability has become a paramount concern in the automation machinery manufacturing sector as companies strive to reduce their environmental footprint and improve operational efficiency. Innovations in eco-friendly materials and energy-efficient manufacturing processes are at the forefront of this transformation. Manufacturers are now exploring the use of biodegradable resources and recyclable materials, which not only minimize waste but also resonate with an increasingly eco-conscious consumer base. By integrating these sustainable practices into their production lines, companies can significantly lessen their impact on the planet while enhancing their brand reputation.

Moreover, advancements in smart automation technologies play a crucial role in promoting sustainability within the manufacturing process. The implementation of IoT devices and data analytics allows manufacturers to closely monitor energy consumption and resource utilization. This real-time data enables businesses to identify inefficiencies, streamline operations, and optimize supply chains, ultimately leading to lower emissions and resource waste. As automation machinery evolves to embrace these technologies, the industry moves toward achieving not just profitability but also a commitment to a sustainable future, reflecting an alignment with global sustainability goals.

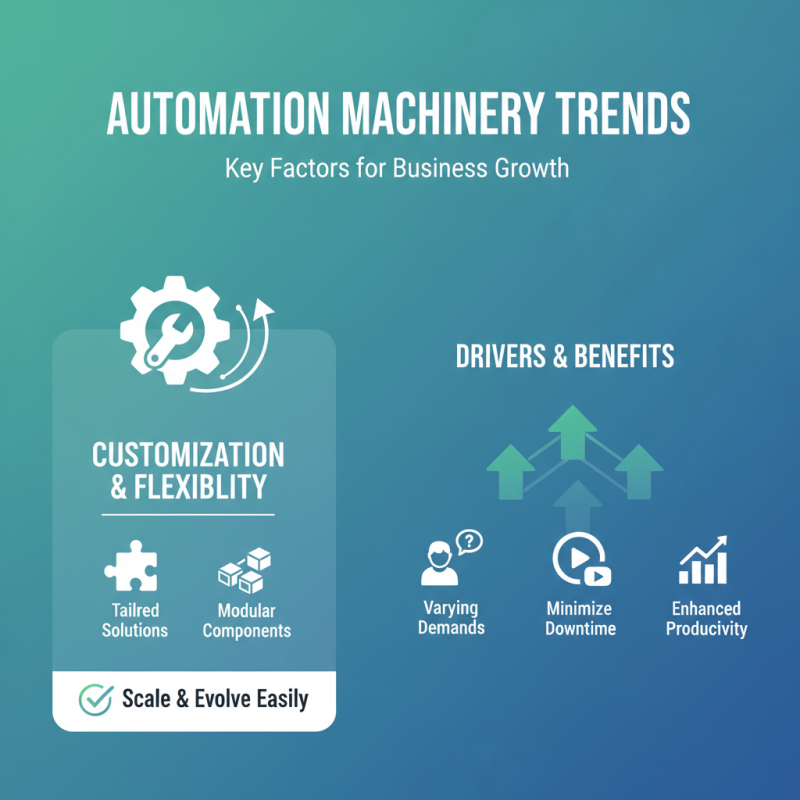

In the ever-evolving landscape of automation machinery manufacturing, customization and flexibility have emerged as critical factors for businesses across diverse industries. Companies are increasingly seeking tailored solutions that can adapt to specific production needs, optimize processes, and improve overall efficiency. This trend is primarily driven by the necessity to meet varying customer demands, minimize downtime, and enhance productivity. Automation systems that offer modular components allow manufacturers to easily scale operations and incorporate advancements without the need for a complete overhaul.

**Tip:** When exploring automation solutions, consider the specific requirements of your operation. Assessing the potential for customization can significantly impact production efficiency and cost-effectiveness. Collaborating with vendors that provide flexible automation systems can lead to tailored setups designed to fit unique workflows.

Another important aspect is the integration of smart technologies that can provide real-time data analytics and machine learning capabilities. These features enable businesses to make informed decisions quickly, allowing them to pivot and adapt to changing market dynamics. The ability to shift machinery configurations seamlessly in response to varying demands enhances operational resilience.

**Tip:** Look for automation machinery that supports easy integration with existing technologies. This will not only streamline your operations but also future-proof your investment by facilitating updates and adaptations as your needs evolve.

We’re here to help and answer your questions.