In the ever-evolving landscape of manufacturing, the extrusion machine stands out as a cornerstone for efficient production processes. As industries increasingly seek ways to enhance productivity while reducing costs, the demand for advanced extrusion technology continues to grow. The year 2023 has witnessed significant innovations in this field, leading to the emergence of several top-tier extrusion machines that not only meet but also exceed performance expectations.

This article delves into the top 5 extrusion machines that have redefined efficiency in manufacturing. Each machine highlighted in this selection has been rigorously evaluated based on factors such as versatility, speed, energy consumption, and overall reliability. The goal is to provide manufacturers with insights into the best options available, enabling them to make informed decisions that align with their production goals. Whether you're involved in plastic, metal, or food processing industries, understanding the capabilities of these extrusion machines will be essential for staying competitive in 2025 and beyond.

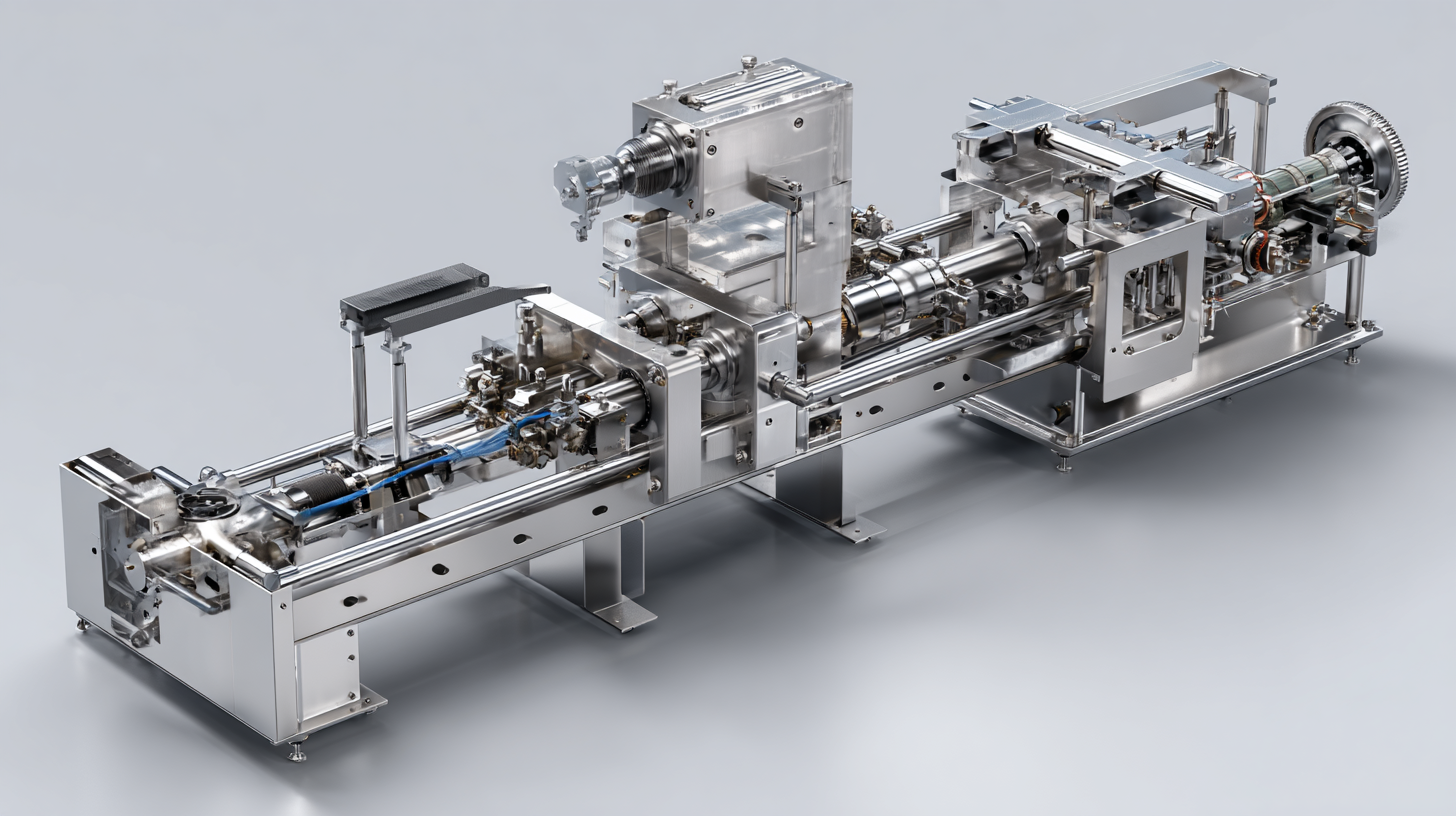

The extrusion industry is witnessing remarkable innovations in 2023, driven by the need for efficiency and sustainability in manufacturing. One of the leading advancements is the integration of smart technology into extrusion machines. These machines are now equipped with IoT capabilities, allowing real-time monitoring and data analysis. This not only enhances productivity but also enables predictive maintenance, reducing downtime and operational costs significantly.

Another significant innovation is the development of energy-efficient extrusion systems, which utilize advanced materials and optimized processes to minimize energy consumption. These machines are designed to operate with lower thermal losses and reduced carbon footprints, aligning with global sustainability goals. Additionally, the introduction of modular extrusion systems allows manufacturers to easily upgrade components and enhance versatility, catering to a wider range of production needs without substantial investments. As these advancements reshape the manufacturing landscape, the focus remains on boosting performance while adhering to eco-friendly practices.

In 2023, the push for efficiency in manufacturing has never been more critical, as industries strive to meet growing market demands while maintaining sustainable practices. As highlighted in the recent trends of strategic emerging industries, the focus is on leveraging advanced technologies to foster what can be termed as "new quality productivity." This concept is pivotal for the modern manufacturing landscape, particularly in the realm of extrusion machinery, where innovations are reshaping production processes.

According to a market research report, the global extrusion machinery market is projected to grow at a CAGR of 5.2% over the next five years, with a significant shift towards high-efficiency machines that can minimize waste and enhance output. Modern extrusion machines incorporate advanced automation and control systems, leading to better process optimization. The implementation of these high-efficiency machines not only boosts manufacturing speed but also reduces energy costs, which is increasingly vital given the rising price of resources and the need for eco-friendly production methods.

Leading manufacturers are now focusing on integrating smart technologies into their extrusion systems, such as IoT-enabled features and predictive maintenance capabilities. This approach not only enhances operational efficiency but also supports proactive decision-making, ensuring that production lines can adapt swiftly to market changes. As industries continue to navigate the complexities of modern manufacturing, investing in high-efficiency extrusion machines will undoubtedly pave the way for robust, sustainable growth.

When selecting extrusion machines for efficient manufacturing in 2023, it is crucial to consider several key features that can significantly enhance production capabilities. One primary aspect is the machine's energy efficiency. According to a report by Smithers Pira, advanced extrusion machines can reduce energy consumption by up to 30% through optimized drive systems and better thermal management. This not only lowers operational costs but also aligns with sustainability goals in the manufacturing sector.

Another important feature is the versatility of the extrusion equipment. The latest machines should accommodate various materials, including advanced plastics and bio-based compounds. Research by MarketsandMarkets indicates that the global demand for versatile extrusion machinery is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026, driven by the shift towards lightweight and eco-friendly materials. Additionally, integration of smart technology such as IoT and AI-driven monitoring systems enhances process control and reduces downtime. These innovations not only increase throughput but also ensure consistent product quality, making them essential for manufacturers looking to stay competitive in a fast-evolving market.

| Machine Model | Production Capacity (kg/h) | Screw Diameter (mm) | Temperature Control Range (°C) | Energy Efficiency Rating | Automation Level |

|---|---|---|---|---|---|

| Model A | 500 | 60 | 180-250 | A++ | Fully Automated |

| Model B | 600 | 65 | 150-230 | A+ | Semi-Automated |

| Model C | 400 | 55 | 170-240 | A | Fully Automated |

| Model D | 300 | 50 | 160-220 | B | Manual |

| Model E | 700 | 70 | 190-260 | A++ | Fully Automated |

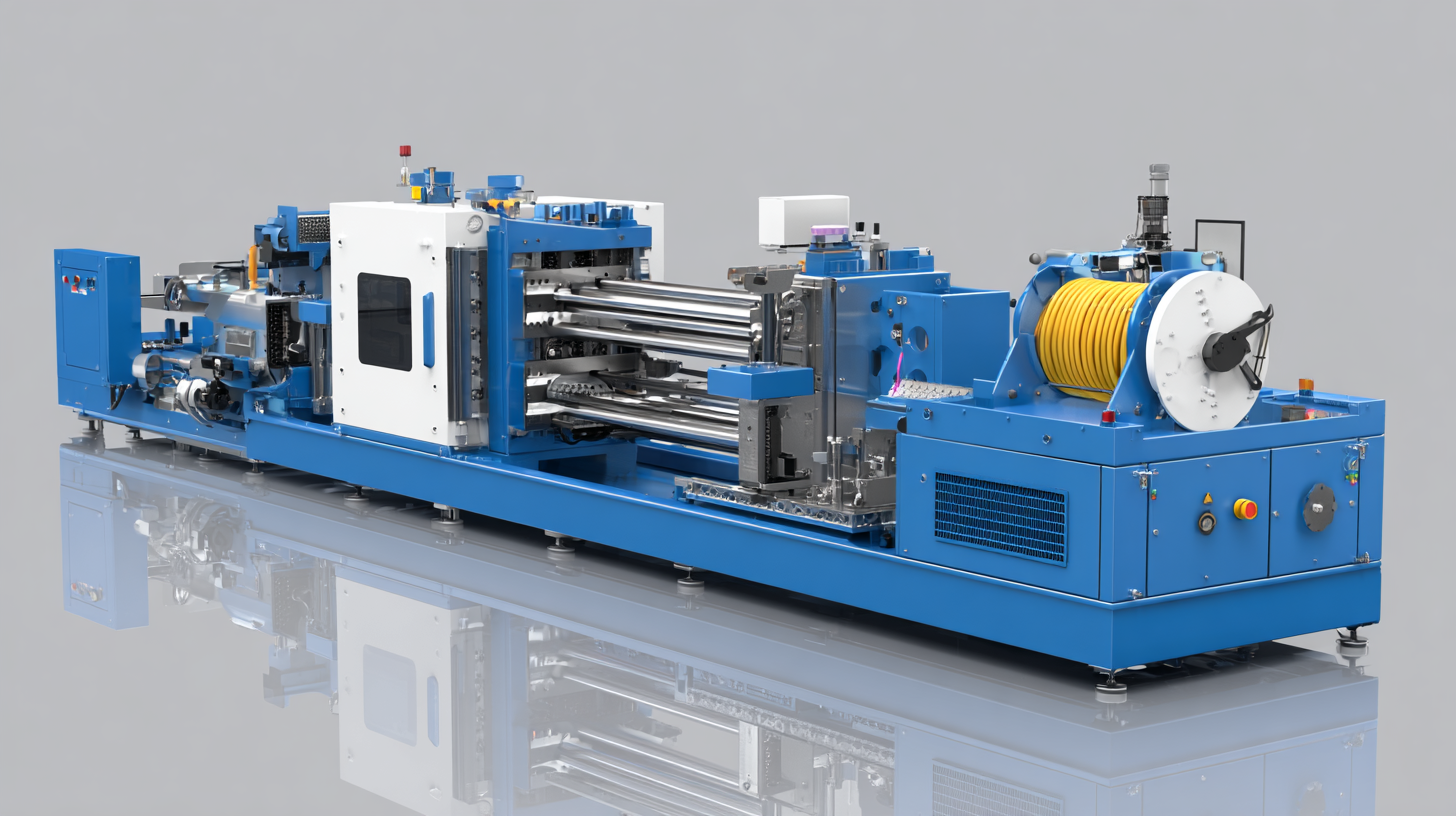

In 2023, the landscape of extrusion machines is marked by significant advancements that enhance efficiency and productivity in manufacturing. A recent report from MarketsandMarkets suggests that the global extrusion equipment market is projected to reach $7.5 billion by 2026, growing at a CAGR of 5.8%. This uptick is driven by the increasing demand for lightweight materials across industries, particularly in automotive and construction sectors. The latest models feature programmable controls and energy-efficient designs, which contribute to both lowering operational costs and minimizing waste.

Among the top extrusion machines, the flagship models demonstrate impressive capabilities, such as improved thermal stability and consistent output quality. For instance, the Xtreme 3000 series boasts a production rate increase of up to 20% compared to its predecessors, as highlighted in the 2023 Global Extrusion Industry Report. Moreover, the integration of IoT technology in machines like the UltraFlex systems allows for real-time monitoring and predictive maintenance, drastically reducing downtime. With these innovations, manufacturers are better equipped to meet rigorous production demands while adhering to sustainability standards.

To maximize productivity when using extrusion machines, it's essential to prioritize proper maintenance and operation practices. Regularly scheduled maintenance can prevent unexpected breakdowns that disrupt production schedules. Operators should ensure that all components are clean and functioning optimally, as even minor issues can lead to significant inefficiencies. Additionally, keeping a detailed log of maintenance activities can help identify recurring problems and inform future strategies.

Another key practice is optimizing machine settings based on material specifications and desired output. Familiarity with the properties of the materials being extruded can significantly enhance the quality of the final product. Operators should experiment with different temperature and pressure settings to find the sweet spot that maximizes output while maintaining product integrity. Training staff to understand these nuances will also contribute to a smoother production flow, allowing for adjustments in real-time and promoting overall efficiency in the manufacturing process.

We’re here to help and answer your questions.