Industrial aluminium profiles play a crucial role in various sectors. They offer strength, durability, and versatility that many materials cannot match. From construction to manufacturing, these profiles serve many applications.

In this article, we will explore the top 10 industrial aluminium profiles. Each profile has unique features that can enhance productivity and efficiency. Some profiles are designed for specific tasks, while others provide general solutions.

Understanding these profiles is essential for anyone in the industry. Choosing the right profile can make a significant difference in performance. However, many overlook important factors when selecting aluminium profiles. It's vital to consider the intended use, load requirements, and environmental factors. By reflecting on these aspects, you ensure you are making informed choices.

Industrial aluminium profiles have gained popularity for their versatility and lightweight nature. The global aluminium extrusion market was valued at approximately $95 billion in 2021 and is expected to grow due to increasing industrial applications. These profiles are commonly used in construction, automotive, and manufacturing, contributing to a more sustainable future.

One significant benefit of aluminium profiles is their resistance to corrosion. This property enhances their lifespan, reducing the need for frequent replacements. Furthermore, they are easily recyclable, aligning with eco-friendly practices. According to a 2022 sustainability report, recycling aluminium saves 95% of the energy needed to produce new aluminium from ore. This energy efficiency is a critical factor for industries aiming to lower their carbon footprint.

However, challenges still exist. The initial investment in precision machining can be high. Some manufacturers struggle with the complexities of designing these profiles to meet specific needs. Misalignment or errors during production can lead to significant waste and increased costs. Continuous improvement in techniques and technology is vital for overcoming these hurdles and maximizing the advantages of industrial aluminium profiles.

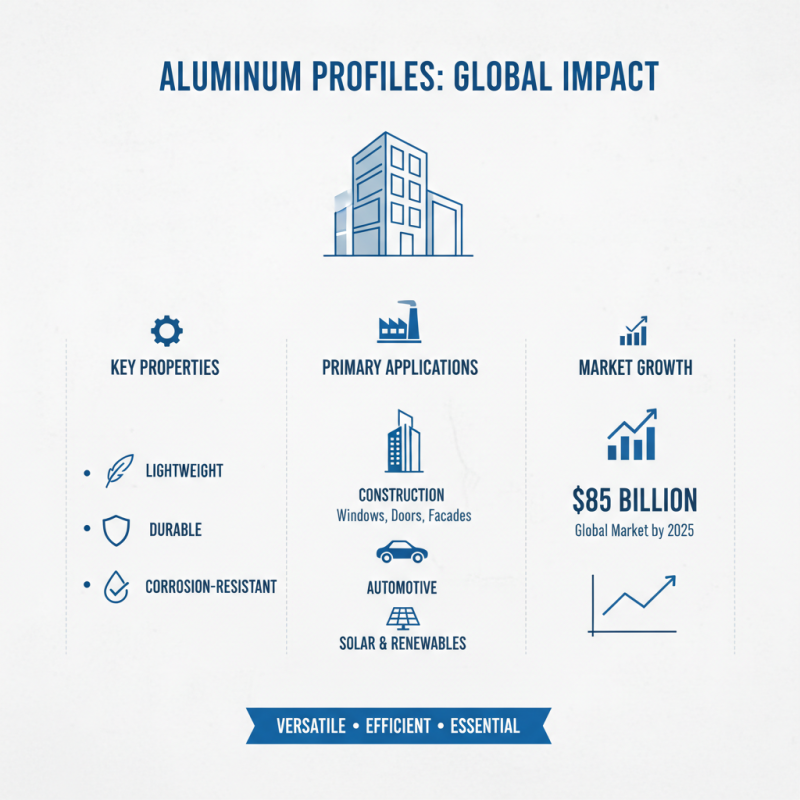

Aluminium profiles are crucial across various industries. They are lightweight, durable, and corrosion-resistant. This makes them ideal for many applications. In construction, they are used for windows, doors, and facades. The global market for aluminium profiles is expected to reach $85 billion by 2025, reflecting their importance.

In the automotive sector, aluminium profiles enhance vehicle performance. They help reduce weight, improving fuel efficiency. Reports show that lightweight materials can improve gas mileage by up to 10%. This reflects the push towards sustainability in manufacturing. However, the challenge is balancing strength with weight.

Electronics also benefit from aluminium profiles. They provide effective heat dissipation for various devices. Studies indicate that efficient thermal management can extend product life. Still, manufacturers often struggle with design complexities. Finding the right balance can be difficult. Issues like optimizing profile thickness can arise, impacting functionality. Such challenges remind us of the need for continuous innovation.

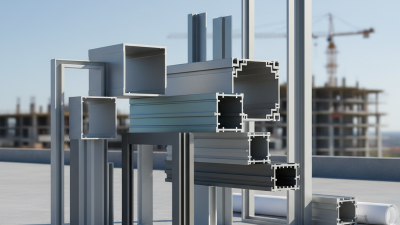

Aluminium profiles are crucial in various industrial applications. The manufacturing process significantly influences their properties and performance. Extrusion is one of the primary methods, where heated aluminium is forced through a die to create specific shapes. This method can produce profiles with complex geometries. According to industry reports, over 80% of aluminium structures use this process.

After extrusion, profiles often undergo processes like anodizing or surface treatment. Anodizing enhances corrosion resistance and improves aesthetic appeal. A report from the International Aluminium Institute notes that anodized aluminium can have a lifespan increase of up to 25%. However, the need for a precise balance in thickness is evident. Poor control can lead to uneven surfaces.

Another crucial method is the bending process. Bending allows profiles to be customized for specific applications. Yet, this aspect requires meticulous attention. Improper bending can lead to weak points in the profile, affecting the overall integrity. The importance of quality control cannot be overstated. Industry data shows that around 15% of defects arise during bending. Continuous innovation in manufacturing processes is vital to overcome these challenges.

When selecting aluminium profiles, consider several critical factors. Thickness and size matter. Thicker profiles often provide better strength. However, they may also add extra weight. This can complicate handling and installation. Balance is key, as an overly heavy profile may be impractical.

Another important aspect is the finish. Anodized finishes provide better corrosion resistance. However, they often come at a higher cost. You might face a trade-off between durability and budget. Think carefully about your specific needs. Will the profile be exposed to harsh environments? If yes, prioritize corrosion resistance.

Don’t overlook customizations. Many projects require unique dimensions. Custom profiles can enhance functionality but can increase lead times. Be prepared for potential delays in your project timeline. Lastly, consult professionals for advice if you have doubts. Their experience can help steer you away from common pitfalls.

The future of aluminium profile manufacturing is evolving rapidly. Advances in technology are reshaping how these profiles are produced and utilized. For instance, automation and artificial intelligence are enhancing production efficiency. This means faster turnaround times and reduced costs, but it also raises questions about job displacement in traditional roles.

Sustainability is a major focus for the industry. Manufacturers are exploring ways to recycle aluminium effectively. This not only lowers waste but minimizes the environmental impact of new production. However, challenges remain in perfecting recycling processes. Many facilities still struggle with processing and logistics. This creates a gap between aspiration and achievement in sustainable practices.

Increased customization is another trend. More industries are seeking tailored solutions to meet their unique needs. This pushes manufacturers to be more innovative. However, higher customization can lead to longer lead times. Balancing efficiency with personalization is crucial. The challenge lies in maintaining quality without sacrificing sustainability or speed.

| Profile Type | Application | Dimensions (mm) | Weight (kg/m) | Future Trends |

|---|---|---|---|---|

| T-Slot Profiles | Modular Structures | 20x20, 30x30 | 0.9, 1.5 | Increased automation and customization |

| Sheet Profiles | Construction, Signage | 1.0, 1.2 | 2.5, 3.0 | Sustainable sourcing and recycling |

| Angle Profiles | Frames, Brackets | 50x50, 40x20 | 2.0, 1.2 | Lightweight design and strength optimization |

| Channel Profiles | Support Structures | 30x60, 40x80 | 3.5, 4.0 | Integration with smart technologies |

| Round Tubes | Piping, Supports | 25, 32 | 1.8, 2.2 | Focus on durability and corrosion resistance |

| Structural Profiles | Heavy-Duty Applications | 100x100, 120x70 | 6.0, 8.0 | Reliance on lightweight materials |

| Flat Bars | General Use, Carpentry | 10x25, 20x40 | 1.0, 2.0 | Adaptation for contemporary designs |

| Custom Profiles | Specialized Applications | Variable | Variable | Personalized solutions for niche markets |

| Extruded Profiles | General Manufacturing | Various Sizes | Variable | Automation and mass production techniques |

We’re here to help and answer your questions.