The evolution of manufacturing industries is pivotal to shaping the future landscape of global production. By leveraging cutting-edge technologies, companies are not only enhancing efficiency but also driving significant economic growth. According to a report by the World Economic Forum, it is projected that the manufacturing sector will contribute approximately $30 trillion to the global economy by 2030, highlighting its crucial role in industrial development and job creation.

In recent years, five key manufacturing industries have emerged as leaders in this revolution: advanced robotics, additive manufacturing, smart manufacturing, biomanufacturing, and sustainable manufacturing. These sectors are not just transforming processes; they are also fostering sustainable practices that meet both consumer demands and environmental standards. For instance, a study by McKinsey shows that embracing sustainability in manufacturing could lead to $3.3 trillion in annual value creation by 2030. As these trends continue to accelerate, the future of manufacturing industries promises to be one marked by innovation, sustainability, and significant economic impact.

The manufacturing sector is undergoing a profound transformation fueled by emerging technologies that are reshaping production processes. According to a report from McKinsey, advanced manufacturing technologies, including automation and artificial intelligence, could potentially boost global GDP by up to $1.2 trillion by 2030. This shift not only enhances efficiency but also drives the development of sustainable practices within the industry. For instance, the integration of IoT devices helps manufacturers monitor operational efficiency in real-time, reducing waste and energy consumption.

As businesses adapt to these technological advancements, they must prioritize training and upskilling their workforce to remain competitive. A survey by the World Economic Forum indicated that 85 million jobs may be displaced by the shift towards automation; however, 97 million new roles will emerge that require advanced technological skills.

Tips: For manufacturers looking to harness these technological changes, fostering a culture of innovation is key. Encourage teams to explore new ideas and solutions that leverage digital tools. Additionally, investing in continuous education programs will equip employees with the skills needed to thrive in this evolving landscape, ensuring businesses maintain a competitive edge while navigating the complexities of future production environments.

In recent years, sustainable practices have become pivotal in transforming manufacturing industries globally. According to the International Energy Agency's 2022 report, manufacturing accounted for nearly 24% of global energy-related CO2 emissions. As industries strive to mitigate their environmental impact, many are adopting circular economy principles that prioritize resource efficiency and waste reduction. For instance, the transition to renewable energy sources, as highlighted in the World Economic Forum's 2023 report, could potentially cut these emissions by up to 70% by the year 2030, illustrating a significant shift towards ecological responsibility.

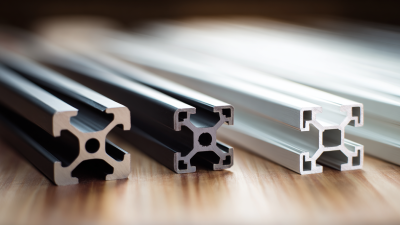

In addition to reducing emissions, sustainability is driving innovation in materials and production processes. The McKinsey Global Institute finds that the adoption of advanced manufacturing technologies can improve resource efficiency by up to 30%. Companies are increasingly investing in smart manufacturing solutions, integrating IoT and AI to optimize operations and reduce resource consumption. For instance, the automotive industry is moving towards electric vehicle production, where sustainable raw materials and processes are reshaping supply chains. This not only aligns with environmental goals but also meets the growing consumer demand for eco-friendly products, positioning these industries for future success.

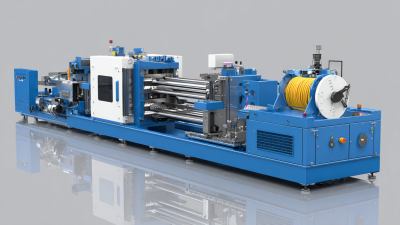

The landscape of global production is undergoing a seismic shift due to the rapid advancement of automation and robotics. These technologies are not merely supplementary tools; they are at the forefront of redefining operational efficiency across various manufacturing industries. By integrating intelligent systems and robotic solutions, companies are dramatically enhancing productivity while minimizing labor costs. The ability to automate repetitive tasks allows human workers to focus on higher-level activities, fostering innovation and creativity within the workplace.

Moreover, the precision and consistency offered by automated systems significantly reduce errors and waste in production processes. Industries such as automotive, electronics, and food processing are leveraging robotics for tasks that require speed and accuracy, leading to higher quality products and faster turnaround times. With the emergence of smart factories, where interconnected devices communicate and optimize production in real-time, the future of manufacturing is poised for unprecedented efficiency. As these technologies continue to evolve, they promise not only to enhance productivity but also to transform the very fabric of how industries operate, paving the way for a more sustainable and responsive global manufacturing ecosystem.

The role of Artificial Intelligence (AI) in the manufacturing sector is increasingly recognized as a transformative force, poised to reshape global production by 2032. The market for AI is projected to grow dramatically, reaching an impressive $1.77 trillion by 2032, with a compound annual growth rate (CAGR) of 29.2% from $294.16 billion in 2025. This remarkable growth underscores the pivotal role AI will play across various industries, particularly in enhancing manufacturing processes.

As companies from the food and beverage sector lead the charge, integrating AI for innovation and efficiency, the potential for AI to streamline production, reduce waste, and improve quality becomes clear. For manufacturers, adopting AI technologies now can create significant competitive advantages and open new avenues for revenue generation.

Tips: Manufacturers should consider starting small by implementing AI in specific areas of their processes, which can lead to gradual scalability. Additionally, staying informed about emerging AI technologies and trends is crucial for making strategic decisions that align with the future landscape of manufacturing. Embracing a culture of continuous learning will also be beneficial as AI evolves.

| Industry | AI Application | Benefits | Projected Growth (%) |

|---|---|---|---|

| Automotive | Predictive Maintenance | Reduced Downtime | 8 |

| Electronics | Quality Control | Decreased Defects | 10 |

| Pharmaceuticals | Drug Development | Faster Research | 12 |

| Aerospace | Supply Chain Optimization | Cost Efficiency | 9 |

| Food & Beverage | Inventory Management | Reduced Waste | 7 |

| Textiles | Pattern Recognition | Enhanced Design | 6 |

| Chemicals | Process Automation | Increased Safety | 5 |

| Construction | Project Management | Improved Timeliness | 11 |

| Metal Fabrication | Robotic Welding | Increased Precision | 8 |

| Renewable Energy | Energy Management | Optimization of Resources | 15 |

The global supply chain landscape is undergoing a significant transformation driven by advanced technologies.

AI plays a pivotal role in enhancing resilience and efficiency, enabling companies to better withstand disruptions posed by climate change, geopolitical tensions, and industrial actions.

By employing AI tools, businesses can optimize their operations, predict risks, and implement strategies that streamline logistics, thus ensuring timely deliveries and minimizing costs.

Moreover, innovations such as blockchain and the Internet of Things (IoT) are reshaping supply chain dynamics in regions like China.

These technologies facilitate enhanced tracking and transparency, empowering organizations to make informed decisions quickly.

Furthermore, sustainable practices are becoming increasingly crucial, as seen in initiatives that tackle pollution and promote cleaner production methods.

This shift is not only beneficial for the planet but also aligns with consumer demand for ethical manufacturing.

Tips for Enhancing Supply Chain Efficiency:

We’re here to help and answer your questions.