In the rapidly evolving landscape of automation machinery manufacturing, experts predict that 2025 will usher in a multitude of trends that are expected to transform the industry. According to Dr. Emily Chen, a leading authority in automation technologies, “The future of automation machinery manufacturing lies in embracing innovation and sustainability, which will define the competitive landscape.” As businesses strive to enhance efficiency and reduce operational costs, the integration of advanced technologies such as artificial intelligence, machine learning, and IoT will become paramount.

Moreover, the emphasis on smart manufacturing processes is likely to revolutionize traditional manufacturing practices, paving the way for increased productivity and adaptability. The rise of collaborative robots (cobots) that work alongside human operators indicates a shift towards a more integrated workforce, aiming to optimize both human and machine capabilities. Additionally, the focus on sustainable practices in automation machinery manufacturing highlights the industry's commitment to reducing its environmental impact while maintaining operational efficiency.

As we explore the top trends shaping the automation machinery manufacturing sector in 2025, it is essential to understand how these developments will not only affect productivity but also redefine industry standards, driving innovation and setting the stage for a more sustainable future.

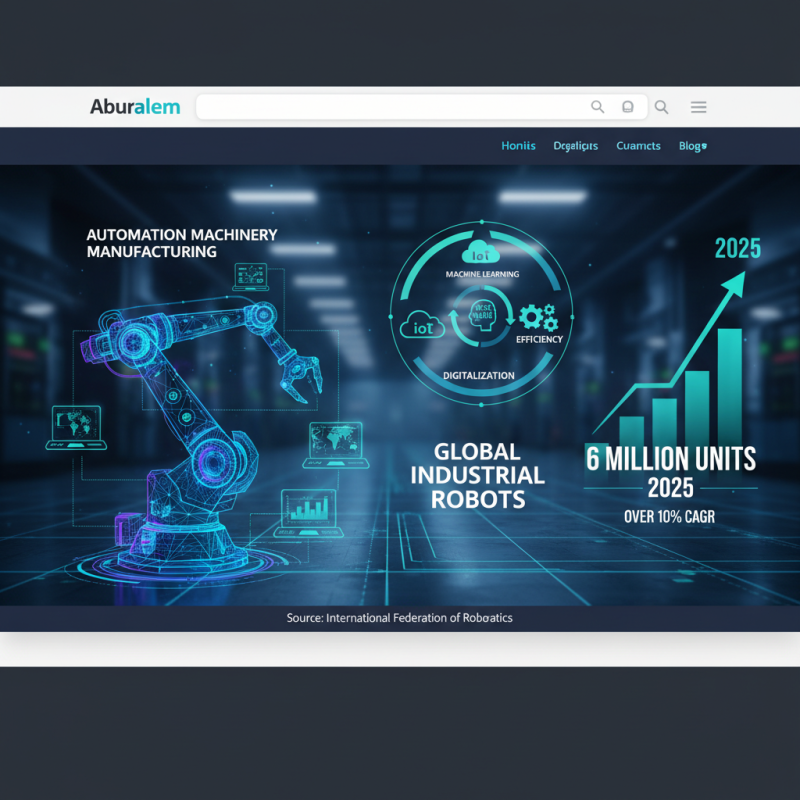

The landscape of automation machinery manufacturing is witnessing a profound transformation propelled by emerging technologies. As industries increasingly embrace digitalization, technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning are becoming integral to improving efficiency and productivity. According to a recent report by the International Federation of Robotics, the global operational stock of industrial robots is expected to reach 6 million units by 2025, reflecting a compound annual growth rate (CAGR) of over 10%. This surge underscores the growing reliance on automation technologies to enhance manufacturing capabilities.

Moreover, advancements in smart manufacturing are paving the way for greater interoperability among machinery. With the implementation of advanced data analytics, companies can optimize their production processes, reduce downtime, and anticipate equipment failures. A study from McKinsey indicates that adopting AI and analytics in manufacturing could unlock $1.2 trillion in economic value globally. As businesses invest in these technologies, the machinery manufacturing sector will likely see an increase in automation solutions that not only streamline operations but also provide real-time insights into performance metrics. This shift towards automation driven by innovative technologies defines the future of manufacturing, positioning organizations to stay competitive in an increasingly complex market.

The integration of AI and machine learning into manufacturing processes is revolutionizing the automation machinery sector, driving efficiency and fostering innovation. According to a report by McKinsey, it is estimated that AI could contribute up to $3.7 trillion annually to the global manufacturing sector by 2025. This staggering figure underscores the potential that AI has in optimizing production lines, predictive maintenance, and inventory management, enabling manufacturers to adapt rapidly to market changes.

Moreover, machine learning algorithms are increasingly being utilized for data analysis and decision-making, allowing manufacturers to anticipate equipment failures before they occur. A report from PwC indicates that nearly 72% of manufacturing executives believe that AI will significantly impact their operations within the next few years. By leveraging real-time data analytics and machine learning capabilities, manufacturers can enhance product quality and minimize waste, resulting in substantial cost savings.

Tips: For manufacturers looking to implement AI and machine learning solutions, starting with a clear strategy is essential. Identify specific areas within your operations that could benefit from these technologies, and consider pilot projects to evaluate their impact. Additionally, investing in staff training and development will ensure that your team is equipped to manage and optimize these advanced systems effectively.

As the automation machinery manufacturing sector evolves, sustainability is emerging as a crucial trend that shapes production practices. According to a recent report from McKinsey & Company, about 60% of companies in the manufacturing sector are prioritizing sustainability initiatives in their operations. This shift is driven by increasing regulatory pressures and a growing consumer demand for environmentally responsible products. In 2025, we expect to see a significant increase in the adoption of green technologies like energy-efficient machinery and waste reduction systems, which play a pivotal role in reducing carbon footprints within the industry.

Furthermore, the concept of circular manufacturing is gaining momentum, promoting the reuse and recycling of materials in automation machinery production. A report by the World Economic Forum indicates that companies that adopt circular economy practices can reduce production costs by up to 30% while enhancing their sustainability profile. Implementing strategies like material innovation, where manufacturers utilize biodegradable or recycled materials, not only mitigates environmental impact but also meets the rising market expectations. As these sustainability trends continue to evolve, they will likely redefine production processes and practices across the automation machinery landscape, leading to a more responsible industry overall.

| Trend | Description | Impact on Sustainability | Year of Adoption |

|---|---|---|---|

| Energy-efficient Machinery | Incorporating energy-saving technologies into machinery design. | Reduces carbon footprint and energy consumption. | 2023 |

| Smart Manufacturing | Leveraging IoT and AI to optimize production processes. | Increases efficiency, reduces waste and energy usage. | 2025 |

| Recyclable Components | Utilizing materials that can be easily recycled in machinery. | Decreases landfill waste and promotes a circular economy. | 2024 |

| Renewable Energy Integration | Integrating solar and wind energy into manufacturing facilities. | Reduces reliance on fossil fuels and lowers emissions. | 2023 |

| Waste Reduction Techniques | Implementing methods to minimize waste during production. | Enhances resource efficiency and reduces environmental impact. | 2025 |

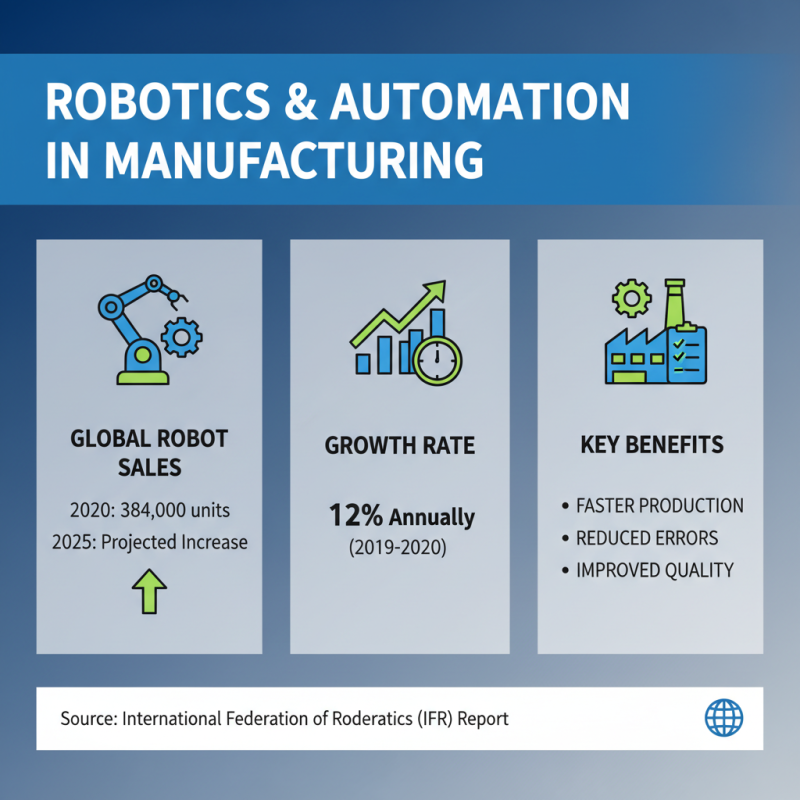

The role of robotics and automation in manufacturing processes has increasingly become a focal point for enhancing efficiency. According to a report by the International Federation of Robotics, global sales of industrial robots reached approximately 384,000 units in 2020, showing a significant growth rate of 12% annually. By 2025, this figure is projected to soar as companies across various sectors recognize the need for automation to remain competitive. The integration of robotics in manufacturing processes not only accelerates production times but also minimizes human error, thus improving overall product quality.

One notable benefit of automation in machinery manufacturing is the dramatic reduction in operational costs. For instance, a 2021 study from McKinsey indicated that organizations implementing advanced robotics can improve productivity by up to 30%. Furthermore, automation technologies enable companies to optimize their supply chains, allowing for faster response times to market changes. As industries grapple with labor shortages and increased demand for high-quality output, the adoption of robotic solutions is expected to be instrumental in ensuring continuity and efficiency in manufacturing operations. As we look toward 2025, the expanding role of robotics stands as a beacon of innovation and resilience in the face of evolving industry challenges.

As the manufacturing sector continues to embrace automation, the skills required for the workforce are evolving rapidly. According to the World Economic Forum's Future of Jobs Report, by 2025, 85 million jobs may be displaced by the shift towards automation, while 97 million new roles could emerge that emphasize human skills. This transformation highlights the urgent need for workers to adapt to new technologies and develop competencies that complement automated systems.

Key skill sets projected to be in high demand include advanced data analytics, programming, and machine learning. A recent study by McKinsey & Company found that nearly 60% of workers in manufacturing will need to reskill or upskill to remain relevant in the industry. Furthermore, soft skills such as problem-solving, adaptability, and collaboration will also become essential as teams integrate both human and machine collaboration. Organizations are increasingly focusing on training programs that emphasize these skills, demonstrating that the future workforce must be versatile and tech-savvy to thrive in an automated environment.

We’re here to help and answer your questions.