In the rapidly evolving landscape of manufacturing, the significance of extrusion profiles cannot be overstated. As industries strive for enhanced efficiency and productivity, understanding the latest developments and trends in extrusion profiles becomes paramount. According to John Smith, a leading expert in the extrusion industry, "The right extrusion profiles can significantly impact production processes, leading to both cost savings and improved product quality." This statement underscores the crucial role that these profiles play in achieving operational excellence.

As we look ahead to 2025, certain extrusion profiles are emerging as essential tools in the quest for innovation and efficiency. These profiles not only streamline production but also offer advanced solutions tailored to meet the diverse needs of various sectors. Exploring the top five extrusion profiles that are set to dominate the market can provide valuable insights for manufacturers aiming to stay competitive. By leveraging these cutting-edge developments, companies can enhance their operational workflows and ultimately drive greater profitability.

In this article, we will delve into the standout profiles that industry leaders should be aware of, equipping them with the knowledge necessary to make informed decisions in the ever-competitive extrusion landscape.

In the ever-evolving landscape of manufacturing, extrusion profiles play a pivotal role in enhancing operational efficiency. The increasing demand for lightweight yet robust materials has spurred the development of innovative extrusion techniques. According to a recent report by Smithers Pira, the global market for extrusion profiles is projected to grow at a CAGR of 4.5%, reaching $56 billion by 2025. This growth is driven by advancements in materials and processes that allow for greater customization and sustainability.

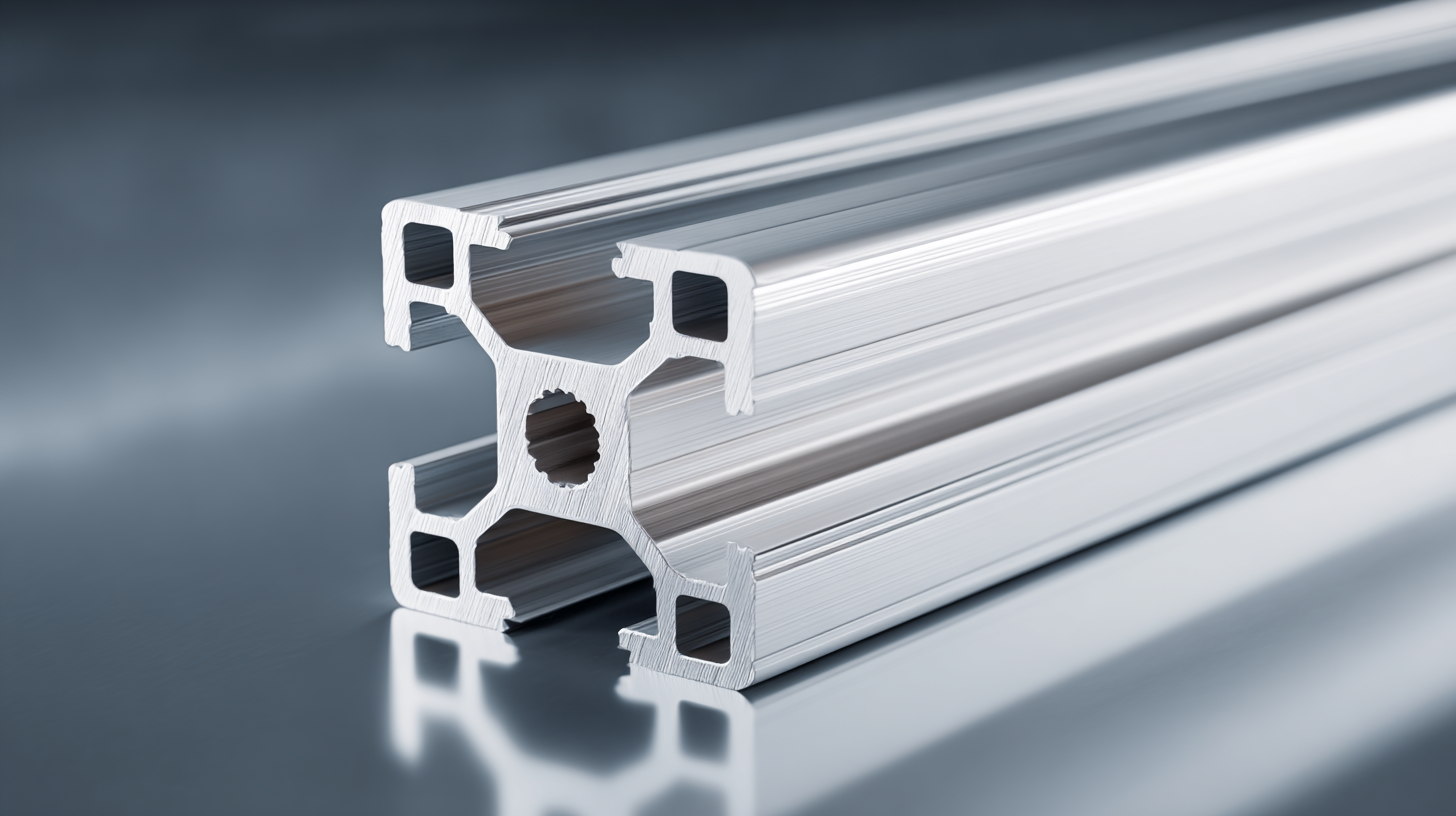

Five extrusion profiles stand out as game-changers in the manufacturing sector. Firstly, the introduction of wood-plastic composites (WPC) is revolutionizing product design, offering both durability and eco-friendliness. Additionally, aluminum extrusion profiles are gaining traction due to their excellent strength-to-weight ratio, which supports the push for energy-efficient solutions. A study by the Aluminum Association highlights that aluminum can reduce energy consumption in transportation by up to 20%, showcasing its significance in achieving sustainability goals. The adoption of thermal break profiles has further enhanced building efficiency, reducing energy loss and contributing to greener construction practices. As manufacturers look to adapt and thrive in a competitive market, understanding these trends is crucial for leveraging extrusion profiles to their full potential.

The selection of materials for extrusion profiles significantly influences their performance and efficiency in various applications. Different materials exhibit distinct properties such as strength, flexibility, thermal resistance, and weight, which can enhance or impede the efficacy of the final product. For instance, aluminum profiles provide a balance between lightness and strength, making them ideal for structural applications where weight reduction is crucial without compromising durability. Conversely, thermoplastics can offer excellent corrosion resistance and lower production costs, potentially enhancing efficiency in industries like automotive and packaging.

Moreover, understanding the specific demands of the application is essential when selecting materials. Materials must not only fit the mechanical requirements but also account for factors like environmental exposure and manufacturing processes. For example, profiles used in outdoor settings may require UV-resistant materials to ensure longevity and performance. Assessing the compatibility of the material with the extrusion process itself—such as flow characteristics and cooling rates—can further improve efficiency by minimizing production waste and optimizing throughput. Thus, informed material selection is critical for maximizing the performance of extrusion profiles in any efficiency-driven project.

Understanding the impact of material selection on extrusion profile performance. The following chart displays the efficiency ratings of various extrusion profiles based on material type.

In 2025, the extrusion profiles industry is set to witness groundbreaking design trends that focus on enhanced efficiency and sustainability. One significant development is the use of biomaterials in extrusion processes. These eco-friendly materials not only reduce environmental impact but also offer impressive performance characteristics. Companies are increasingly investing in bio-based polymers that maintain the strength and durability needed for various applications while being recyclable and biodegradable. This shift towards greener solutions aligns with global sustainability goals and resonates with consumers who are becoming more eco-conscious.

Another trend shaping the future of extrusion profiles is the integration of smart technology. The incorporation of IoT devices and sensors into extrusion systems allows for real-time monitoring and data analytics, optimizing production processes. This technological advancement enables manufacturers to identify inefficiencies quickly and implement corrective measures immediately. Additionally, smart extrusion profiles can adapt to varying environmental conditions, ensuring consistent quality and performance. As the industry evolves, these innovative designs will play a pivotal role in meeting the demands of a rapidly changing market while maintaining high efficiency.

The extrusion profile production landscape is evolving rapidly, driven by advanced technologies that enhance efficiency and contribute to growth in the plastics extruded market, projected to reach USD 259.21 billion by 2034. Companies are increasingly adopting innovative solutions to optimize their processes, thereby improving product quality and reducing waste. By leveraging contemporary advancements such as AI, laser technology, and automation, manufacturers can significantly enhance their extrusion profiles, making them more sustainable and market-oriented.

Tips: To maximize efficiency, consider integrating AI-driven analytics into your production workflow. This can help identify bottlenecks and streamline processes. Additionally, investing in laser technology can enhance precision and reduce operational costs. Regular training for your workforce on new technologies can foster a culture of continuous improvement and innovation.

As seen in recent developments, businesses like Emirates Extrusion Factory are celebrating milestones while transitioning to tech-driven production methods. This shift is critical not only for staying competitive but also for meeting the rising global demand for high-quality extrusion profiles. Adopting these advanced technologies will undoubtedly pave the way for enhanced efficiency and sustainability in the extrusion industry.

When evaluating extrusion profiles for enhanced efficiency in 2025, understanding key metrics is essential. These metrics include material utilization efficiency, cycle time reduction, and energy consumption metrics. Material utilization efficiency measures how much of the raw material is converted into finished products, highlighting potential waste reduction opportunities. By tracking this metric closely, manufacturers can adjust their processes to improve yield and minimize costs.

Tips: To improve material utilization, consider investing in advanced simulation software that predicts potential inefficiencies before production. Additionally, regular training of operators on best practices can significantly impact overall output quality.

Another important metric is cycle time reduction, which looks at the time required for producing an extrusion profile. Shorter cycle times not only boost productivity but also increase capacity without the need for additional resources. Monitoring this metric can help identify bottlenecks in production and areas for automation.

Tips: Implementing lean manufacturing techniques can help streamline processes and eliminate waste, leading to faster production cycles. Regularly reviewing and optimizing the workflow can also contribute to significant time savings.

We’re here to help and answer your questions.