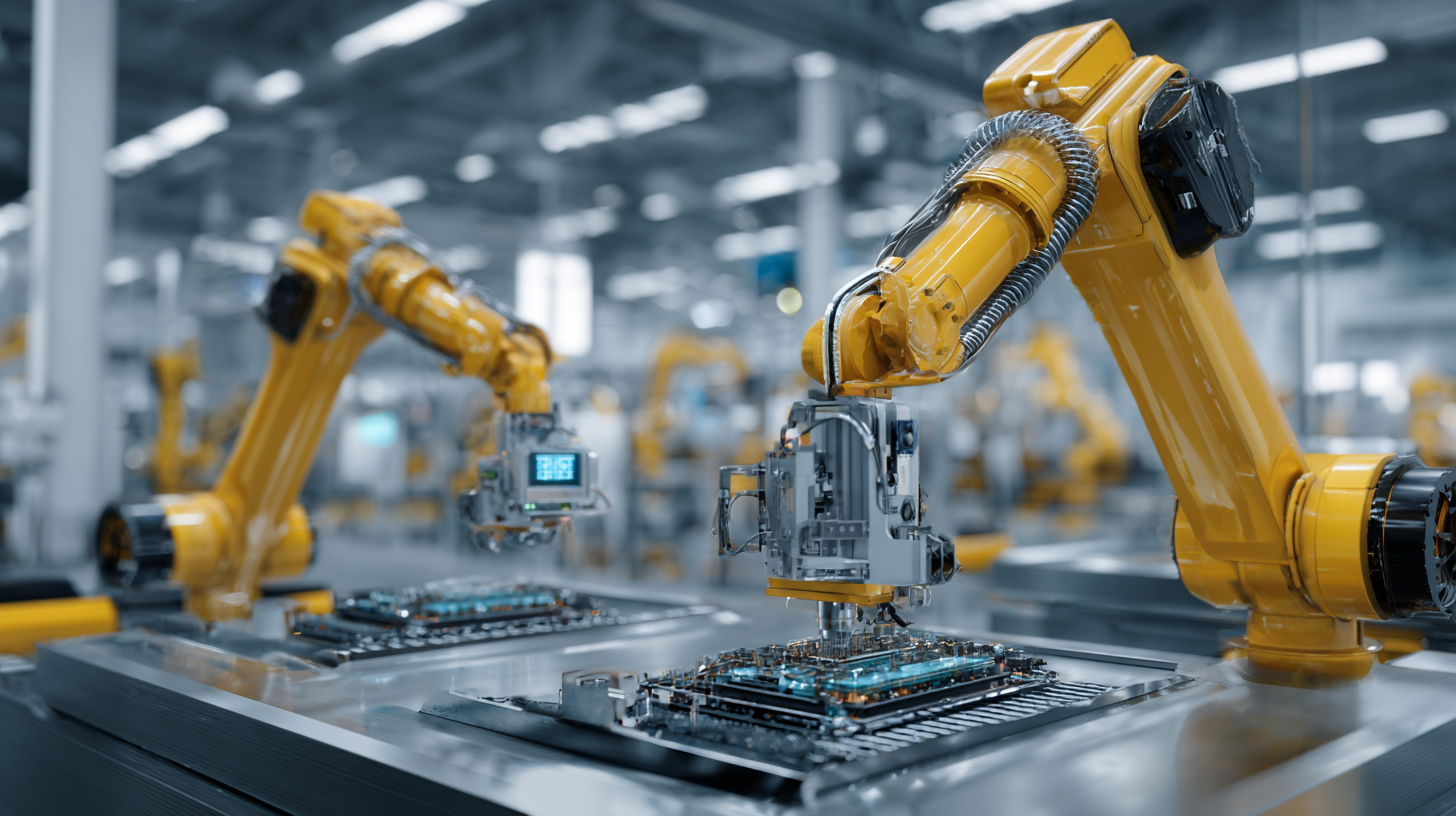

In the rapidly evolving landscape of manufacturing solutions, the integration of smart automation technologies is transforming how industries operate, driving unprecedented levels of efficiency and productivity. Expert Dr. Emily Johnson, a leading authority in manufacturing systems optimization, has stated, "The future of manufacturing lies in the seamless integration of automation technologies, enabling businesses to achieve both flexibility and precision." This insight underscores the growing importance of innovative automation in streamlining processes and reducing operational costs.

As manufacturers seek to remain competitive in a fast-paced global market, adopting smart automation solutions becomes imperative. These technologies not only enhance operational efficiency but also pave the way for smarter decision-making through data-driven insights. With the emergence of advanced robotics, artificial intelligence, and IoT (Internet of Things), the potential for elevating manufacturing solutions to new heights is immense.

Organizations that embrace these technological advancements are better positioned to respond to market demands, improve product quality, and optimize resource allocation. The shift towards automation in manufacturing is not merely a trend, but a revolutionary movement that promises to redefine the capabilities and future direction of the industry. As highlighted by Dr. Johnson, it is essential for manufacturers to harness these innovations to thrive in an increasingly complex environment.

The evolution of manufacturing is significantly influenced by the adoption of Industry 4.0, which emphasizes the integration of smart automation technologies. Reports indicate that by 2025, the global smart factory market is expected to exceed $500 billion, highlighting the accelerating shift towards automated solutions. Smart automation not only streamlines production processes but also enhances data collection and real-time analytics, allowing manufacturers to fine-tune operations and reduce waste significantly.

The evolution of manufacturing is significantly influenced by the adoption of Industry 4.0, which emphasizes the integration of smart automation technologies. Reports indicate that by 2025, the global smart factory market is expected to exceed $500 billion, highlighting the accelerating shift towards automated solutions. Smart automation not only streamlines production processes but also enhances data collection and real-time analytics, allowing manufacturers to fine-tune operations and reduce waste significantly.

*Tip: To maximize the potential of smart automation, start small by automating repetitive tasks. This can provide immediate benefits and valuable insights into more extensive automation opportunities in the future.*

The transformation brought forth by Industry 4.0 is evident in how manufacturers utilize IoT devices, AI, and machine learning. According to a McKinsey report, companies implementing smart automation technologies have reported efficiency gains of up to 30%. Such enhancements enable manufacturers to respond swiftly to market demands and maintain a competitive edge.

*Tip: Invest in training your workforce to adapt to these technologies. Upskilling employees ensures that they are equipped to operate sophisticated automation systems, leading to better utilization of resources and improved productivity.*

The impact of automation technologies on manufacturing productivity has been profound and continues to evolve. According to a report by the International Federation of Robotics, global industrial robot sales reached approximately 465,000 units in 2021, a rise of 27% compared to the previous year. This surge in automation adoption has allowed manufacturers to enhance production speed and reduce errors, significantly increasing overall efficiency. In fact, a study by McKinsey & Company revealed that companies that invested in automation technologies saw productivity boosts of up to 30% within the first year of implementation.

Moreover, the trend towards smart automation is reshaping the manufacturing landscape, with predictions indicating that by 2025, nearly 80% of manufacturing processes will incorporate some level of automation. The World Economic Forum highlights that integrating IoT and AI into production lines can enhance decision-making processes and streamline operations, thus improving output quality and consistency. This transformation is not just about robots on the factory floor; it also encompasses data analytics and machine learning, which drive predictive maintenance and optimize supply chain logistics, ultimately resulting in a more resilient manufacturing ecosystem.

| Automation Technology | Adoption Rate (%) | Impact on Productivity (%) | Cost Reduction (%) | ROI (Years) |

|---|---|---|---|---|

| Robotic Process Automation | 75 | 30 | 20 | 1.5 |

| Artificial Intelligence | 60 | 40 | 25 | 2.0 |

| Internet of Things (IoT) | 50 | 35 | 15 | 3.0 |

| Machine Learning | 55 | 50 | 30 | 1.8 |

| Additive Manufacturing (3D Printing) | 45 | 25 | 10 | 4.0 |

Implementing smart automation technologies in production lines presents a

compelling cost-benefit scenario for manufacturers aiming to enhance

operational efficiency. By automating repetitive tasks, companies can significantly

reduce labor costs while minimizing human errors. Furthermore, smart automation systems

can operate 24/7 without the need for breaks, translating to higher output and

improved productivity. Initial investments in automation equipment and software can

be substantial, but the long-term savings achieved through increased efficiency often

outweigh these upfront costs.

Moreover, the integration of data analytics within smart automation allows manufacturers to optimize their processes continuously. Real-time monitoring of production lines helps identify bottlenecks and inefficiencies, facilitating timely adjustments that further enhance productivity. The ability to predict maintenance needs through smart sensors can also lead to reduced downtime, contributing to an overall more resilient production environment. In this context, the cost-benefit analysis not only highlights immediate financial savings but also underscores the strategic advantages of adopting smart automation, positioning companies for sustained growth in an increasingly competitive market.

In recent years, numerous manufacturing companies have embraced smart automation technologies, resulting in significant efficiency gains. For instance, a case study of a leading automotive manufacturer highlights how the integration of robotic arms in the assembly line reduced production time by 30%. By automating repetitive tasks, the company not only accelerated its production rate but also enhanced the precision of assembly, leading to fewer defects and lower operational costs.

Another compelling example comes from a consumer electronics firm that implemented automated inventory management systems. This technology enabled real-time tracking of components, which streamlined the supply chain and reduced delays caused by stockouts. The result was a 25% improvement in order fulfillment, allowing the company to meet customer demands more effectively. These successful automation initiatives demonstrate how strategic technology implementation can transform manufacturing processes, yielding higher efficiency and competitiveness in the market.

This chart displays the impact of smart automation technologies on manufacturing efficiency. The increase in efficiency is revealed through comparative analysis before and after automation implementation.

As the manufacturing landscape evolves, the integration of smart automation technologies is set to revolutionize efficiency. In the next decade, we can anticipate significant innovations that will redefine production processes. Advanced robotics, equipped with artificial intelligence, will enable greater precision and adaptability in manufacturing lines. These systems will be capable of learning from their environments, optimizing operations in real-time, and ultimately reducing waste and downtime.

Moreover, the advent of the Internet of Things (IoT) will usher in unprecedented connectivity among machines and systems. This connectivity will facilitate predictive maintenance, where machines can alert operators to potential failures before they occur, minimizing costly disruptions. Additionally, digital twins—virtual replicas of physical assets—will play a pivotal role in simulating and optimizing production scenarios. These tools will assist manufacturers in making data-driven decisions, leading to enhanced productivity and more sustainable practices. As we look ahead, the future of manufacturing will be characterized by smarter, more integrated systems that promise not only efficiency but also resilience in an ever-changing market.

We’re here to help and answer your questions.